Aluminum Foils

Providing Professional Solutions

Product Specifications

| Series | Alloy / Grade | Temper | Thickness (mm) | Width (mm) |

|---|---|---|---|---|

| 1000 Series | 1100, 1145, 1050, 1060, 1070, 1200, 1235 | O, H14, H16, H18, H19, H22, H24, H26 | 0.0045 – 0.2 | 3 – 1800 |

| 3000 Series | 3003, 3004, 3005 | O, H14, H16, H18, H19, H22, H24, H26 | 0.0045 – 0.2 | 3 – 1800 |

| 5000 Series | 5052, 5A02 | O, H14, H16, H18, H19, H22, H24, H26 | 0.0045 – 0.2 | 3 – 1800 |

| 7000 Series | 7072 | O, H14, H16, H18, H19 | 0.0045 – 0.2 | 3 – 1800 |

| 8000 Series | 8006, 8011, 8021, 8079 | O, H14, H16, H18, H19, H22, H24, H26 | 0.0045 – 0.2 | 3 – 1800 |

YUTWIN New Materials

China’s Aluminum Material Expert

YUTWIN New Materials supplies a full range of aluminum foil products, offering diversified specifications, stable quality, and reliable performance to meet the needs of food packaging, pharmaceutical packaging, industrial applications, and customized solutions.

Characteristics of Aluminum Foil

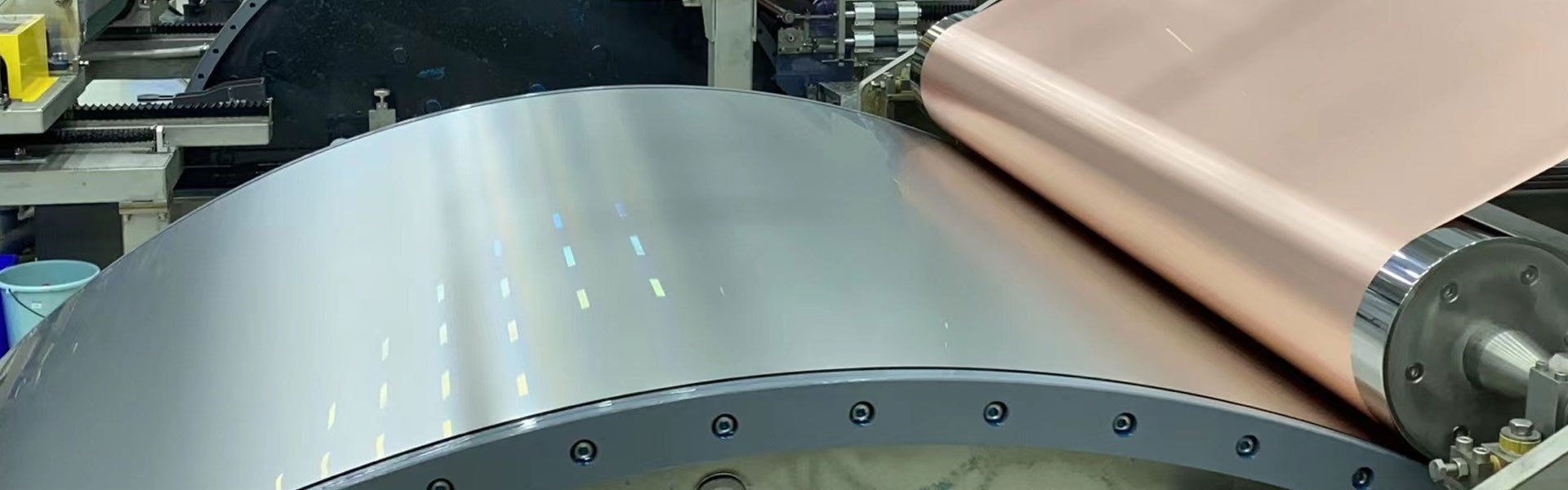

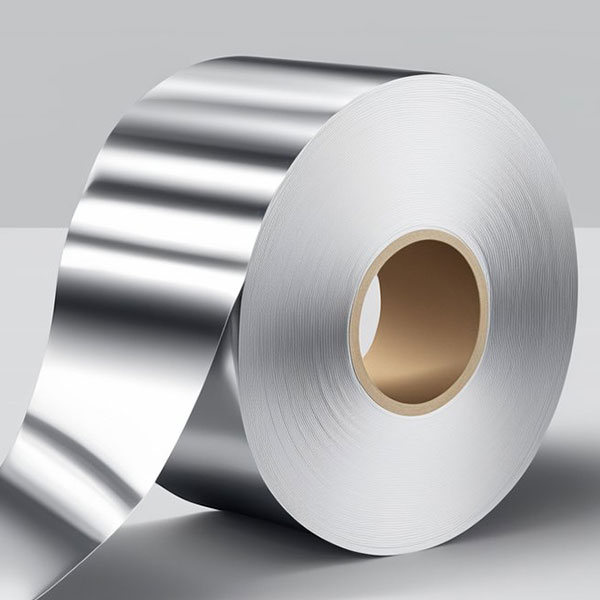

Aluminum foil is a thin, sheet-like material crafted from high-purity aluminum or premium aluminum alloys, manufactured through sophisticated hot-rolling or cold-rolling processes. With a typical thickness ranging from 0.0045 to 0.2 mm, it strikes an ideal balance between ultra-lightweight and structural integrity. It has many excellent properties, making it widely used in both industrial and daily applications.

☑ Lightweight and High Strength

Aluminum foil has low density and light weight while maintaining good strength and toughness, helping reduce overall material weight.

☑ Excellent Barrier Properties

It provides outstanding resistance to light, moisture, gases, and odors, effectively protecting product quality.

☑ Excellent Ductility and Flexibility

Aluminum foil can be easily rolled, folded, and formed, making it suitable for complex shapes and high-precision packaging.

☑ Good Corrosion Resistance

A natural oxide layer forms on the surface, offering resistance to air, water, and many chemical substances.

☑ Good Thermal and Electrical Conductivity

Aluminum foil conducts heat and electricity efficiently and is widely used in heat dissipation, insulation, and electronic applications.

☑ High and Low Temperature Resistance

It remains stable under both high- and low-temperature conditions, suitable for freezing, baking, and industrial thermal processes.

☑ Safe, Hygienic, and Non-Toxic

Food-grade aluminum foil meets safety standards and can be used in direct contact with food and pharmaceuticals.

☑ Recyclable and Environmentally Friendly

Aluminum foil is 100% recyclable, energy-saving, and environmentally friendly, supporting sustainable development.

Main Applications of Aluminum Foil

Food PackagingAluminum foil stands as a multi-functional staple across food packaging, daily use, industrial manufacturing, and construction decoration—delivering unrivaled protection, thermal performance, and adaptability for diverse scenarios.

Categories of Aluminum Foil

Heavy Duty Foils

0.018 – 0.05mm

Thickness ranges from 0.1 to 0.2 mm. Heavy gauge foil is typically used for industrial purposes, such as heat sinks, shielding materials, or architectural decoration.s It offers good strength and rigidity, making it suitable for products that require durability or load-bearing capacity.

Medium Duty Foils

0.012 – 0.018mm

Thickness ranges from 0.01 mm to less than 0.1 mm. This type of foil combines flexibility with a certain level of strength and is widely used in food packaging, baking, household kitchen applications, as well as pharmaceutical and cosmetic packaging.

Light Duty Foils

0.006 – 0.012mm

Light gauge foil refers to aluminum foil whose thickness in millimeters , typically less than 0.01 mm, for example. Light duty foil is extremely flexible and highly pliable, allowing it to be easily rolled, folded, or conformed to complex surfaces. It is ideal for high-precision packaging, food preservation, and specialized industrial applications.

Temper of Aluminum Foil

Aluminum foil can be classified into different tempers based on rolling and annealing processes, with each temper exhibiting distinct physical properties and suitable applications.

Hard Foil

Temper: H18

Hard aluminum foil is foil that has been rolled but not annealed. It has higher hardness and strength but lower ductility. If degreasing is not performed, its surface may contain some residual oil or impurities. Hard foil is typically used in applications requiring high strength, wear resistance, or load-bearing capacity, such as heat sinks, shielding layers, or construction materials.

Semi-Hard Foil

Temper: H14 / H24

Semi-hard foil has hardness and strength between hard and soft foil, offering moderate flexibility. It is suitable for forming processes without easy cracking. Semi-hard foil is widely used in food containers, baking sheets, packaging materials, and light industrial parts, making it one of the most commonly applied foil tempers in both industrial and daily use.

Soft Foil

Temper: 0

Soft aluminum foil is foil that has been fully annealed after rolling, making it highly pliable with a smooth, oil-free surface. Its excellent ductility allows it to be easily folded, rolled, or conformed to complex shapes. Soft foil is ideal for high-precision food packaging, pharmaceutical packaging, and specialized industrial applications. It is also the most common foil used in household cooking and packaging.

Surface Finish of Aluminum Foil

During production, aluminum foil can undergo rolling, polishing, or annealing to achieve different surface finishes, meeting various packaging and industrial application requirements.

Shiny Foil

Through precision rolling and finishing processes, the surface is smooth and highly reflective. Its bright surface gives the aluminum foil excellent light reflection properties and an attractive appearance, making it suitable for both functional and decorative applications.

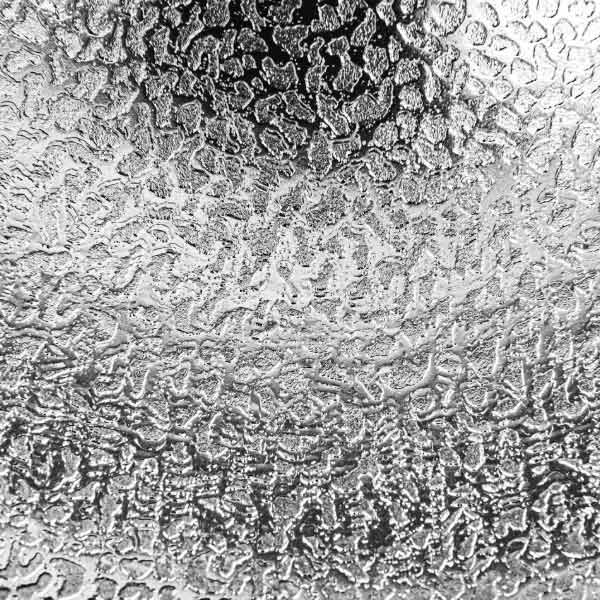

Dull Foil

Compared to shiny foil, dull foil has lower reflectivity and a softer, more uniform appearance. It is lightweight, flexible, corrosion-resistant, non-toxic, and easily processed through methods such as forming, laminating, coating, or printing.

Processing of Aluminum Foil

Aluminum foil can undergo various processing techniques during production and application to achieve different functionalities and surface appearances.

Plain Foil

Plain foil refers to aluminum foil that is rolled but not subjected to any additional processing, also known as bright foil. Its surface is naturally smooth, retaining the original metallic luster. Plain foil is suitable for general packaging or industrial purposes and can serve as a base material for further processing.

Embossed Foil

Embossed foil is aluminum foil with patterns or textures pressed onto its surface. Embossing enhances both aesthetics and friction or rigidity, making it widely used in food packaging, candy wrappers, decorative materials, and handicrafts.

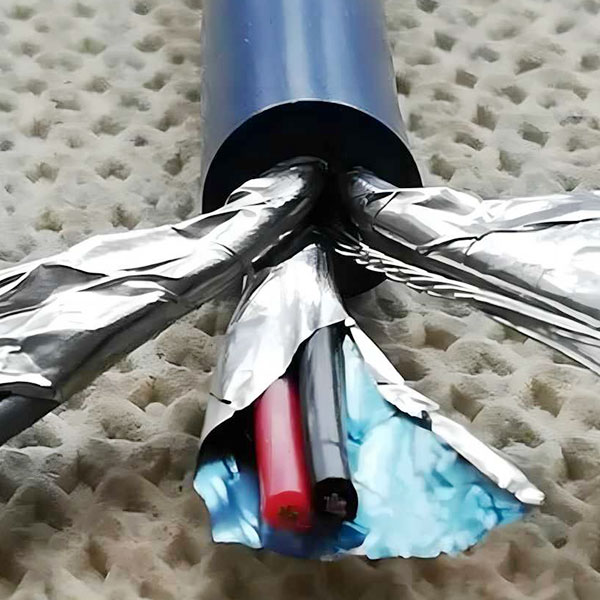

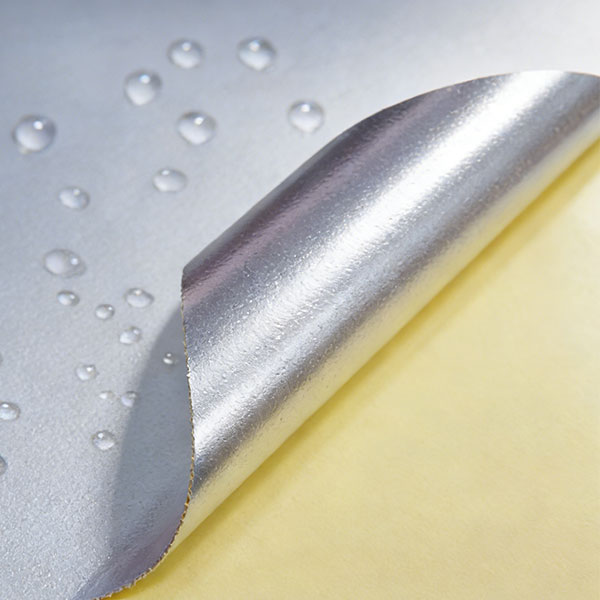

Laminated / Composite Foil

Composite foil is produced by bonding aluminum foil with paper, plastic films, or cardboard to form a multilayer material. It combines aluminum foil’s barrier properties (moisture-proof, light-proof, gas-proof) with the flexibility or printability of other materials, making it ideal for premium food packaging, pharmaceutical packaging, and industrial protective packaging.

Coated Foil

Coated foil is aluminum foil with resins, varnishes, or non-stick coatings applied to the surface to improve corrosion resistance, non-stick performance, or visual appeal. This foil is made by applying a layer of adhesive to one side of an aluminium foil and then coating it with a protective layer.