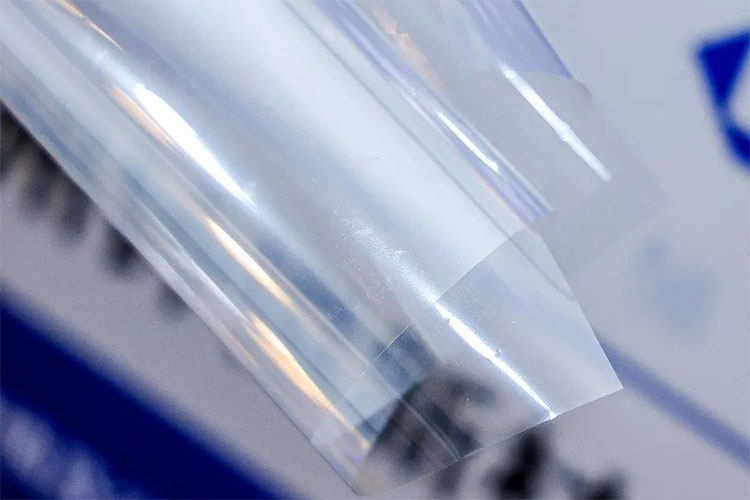

It is a multi-layer composite material made by laminating polyester (PET film) with aluminum foil through a bonding process, and it is widely used across various industries. The laminated aluminum foil from Yutewin new materials features high density, stable barrier properties, excellent interlayer adhesion, and strict quality control, ensuring outstanding reliability and consistency in applications such as food, pharmaceuticals, and electronics.

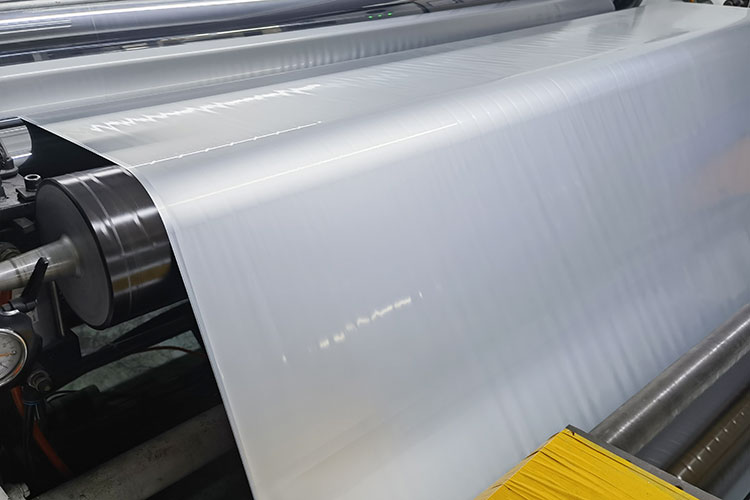

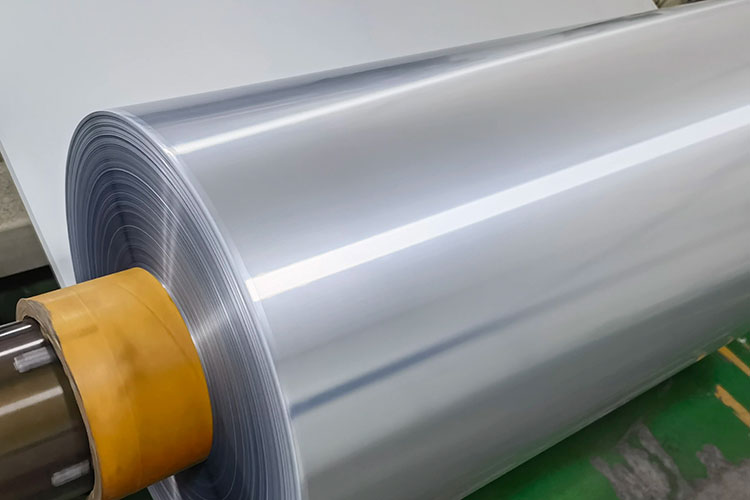

What is PET film?

PET film is a high-performance thermoplastic polyester film material made of polyethylene terephthalate (PET). It is manufactured through processes such as melt extrusion and stretching (usually biaxially oriented BOPET), and possesses high strength, high transparency, and excellent dimensional stability.

Main characteristics of PET film

- High mechanical strength: High tensile strength, not easily torn.

- Good heat resistance: Can withstand high processing temperatures.

- Excellent dimensional stability: Low heat shrinkage.

- Good electrical insulation properties.

- Smooth surface, suitable for printing and coating.

- Good chemical resistance.

Advantages of PET Laminated Aluminum Foil

- Superior Barrier Properties

Aluminum foil possesses excellent oxygen barrier, moisture barrier, and light barrier capabilities, effectively extending product shelf life.

- Enhanced Overall Strength

The PET layers strengthen the tensile and puncture resistance of the composite structure, improving packaging durability.

- Better Heat Processing Performance

Suitable for heat sealing, retorting, and high-temperature sterilization processes.

- Excellent Printability and Appearance

The PET surface is suitable for high-quality printing, enhancing product quality.

- Stable Structure, Less Prone to Delamination

Through professional lamination processes, it boasts high peel strength and strong interlayer bonding.

Main Structure

Specifications

| Surface color | Silver or other printing multi-colors. |

| Thickness: | 7, 8, 10, 12, 15, 18, 25, 50, 75, 100um or others. |

| Surface treatment | Single side or double sides metalling on PET base film. |

| Aluminum alloy layer | 1235, 8011, 8021, 8079 |

| Width/Length | 20mm~2500mm x 1000m~38000m per roll. |

Processing Craftsmanships

Usually, there are three well-established lamination processes used to apply a thin adhesive layer between two substrates.

| Process | Advantages | Limitations |

|---|---|---|

| Dry Lamination | Suitable for combining various substrates; flexible for small and medium batch production | A small amount of solvent residue may remain in the final laminated foil |

| Solvent-Free Lamination | No solvent used in adhesive coating; more environmentally friendly | Generally not suitable for bonding very high-barrier films or complex structures |

| Extrusion Lamination | Uses thermoplastic resins instead of polyurethane adhesive; excellent for food-contact safety | Economical mainly for large-volume production due to higher equipment and setup costs |

Applications of PET Laminated Aluminum Foil

Food Packaging Industry

- Snack Bags.

- Coffee Bags.

- Dairy Product Flexible Packaging.

- Condiment Composite Packaging.

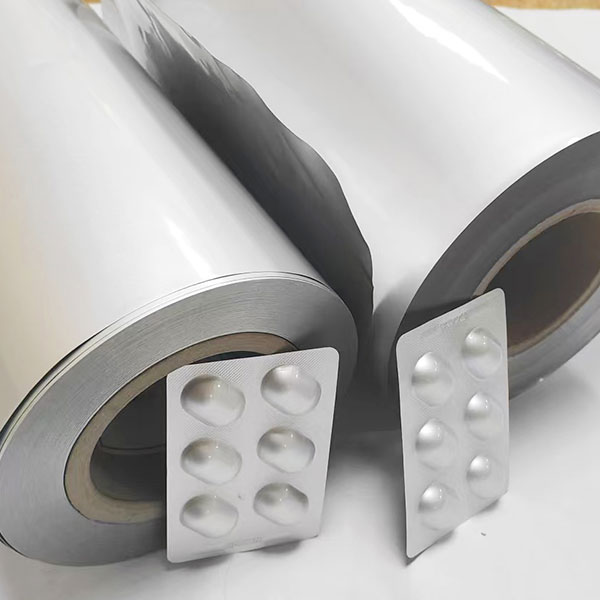

Pharmaceutical and Medical Industry

- Pharmaceutical Flexible Packaging.

- Medical Aseptic Packaging.

- Composite Blister Materials.

Daily Chemicals and Personal Care

- Facial Mask Bags.

- Cosmetic Packaging.

- Wet Wipes Composite Film.

Electronics and Electrical Industry

- Cable Shielding Materials.

- Battery Soft Pack Structures.

- Insulating Composite Materials.