Blister foil (also called pharmaceutical blister lidding foil) is a type of aluminum-based packaging material used to seal tablets, capsules, and other solid-dose medicines in blister packs. It acts as the barrier layer that protects products from moisture, oxygen, light, and contamination. PTP (Press Through Pack) blister is the most common type of packaging.

Features

- Easy to peel, gentle on hands.

- Controllable peel strength.

- Excellent moisture and oxygen barrier properties.

- Printable batch numbers and logos.

Common Specifications

| Category | Specification |

|---|---|

| Common Aluminum Alloys | 8011-O, 8021-O |

| Common Thickness | 20 μm, 25 μm, 30μm |

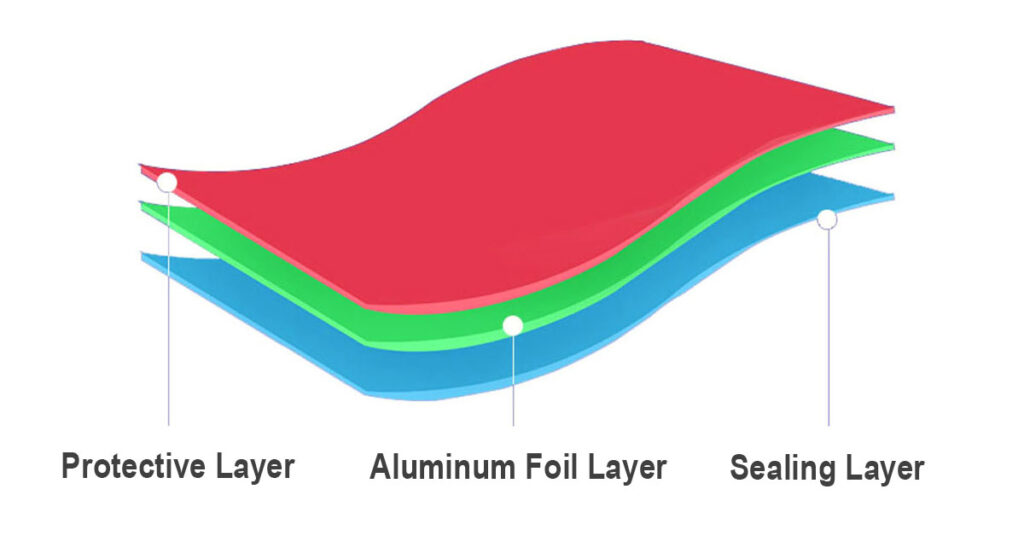

Structure of Blister Foil

A typical blister foil is a multi-layer laminated material.

Aluminum Foil Layer

Provides excellent barrier properties (moisture, oxygen, light).

Common alloy: 8011-H18 / 8011-O

Protective layer

Enhances adhesion between aluminum and heat-seal coating.

Heat Seal Lacquer (HSL)

Allows the foil to be heat-sealed onto PVC, PVDC, PET, or PP blister films.

Main Function

Blister foil is used as the lidding material in pharmaceutical blister packaging.

It works together with:

- Forming film (PVC / PVDC / PET).

- Cold-form aluminum (for Alu-Alu packs).

Applications include:

- Tablets.

- Capsules.

- Soft gels.

- Nutraceuticals.