Aluminum foil containers are widely used in food packaging, catering, and household scenarios due to their safety, heat conductivity, and recyclability. Their manufacturing process is a precise combination of material preparation, mechanical forming, and quality control, which can be divided into six key steps, ensuring the final products meet food-grade standards and practical application needs.

1. Raw Material Selection and Preparation

The production of aluminum foil containers starts with high-quality food-grade aluminum alloys, mainly from the 3000 series (such as 3003) and 8000 series (such as 8011 and 8006) aluminium ingots. These alloys are selected for their excellent ductility, corrosion resistance, and non-toxicity—critical properties for forming and food contact. 8006 aluminum foil is specifically used for wrinkle-free containers, while 3003 alloy is suitable for products requiring better corrosion resistance.

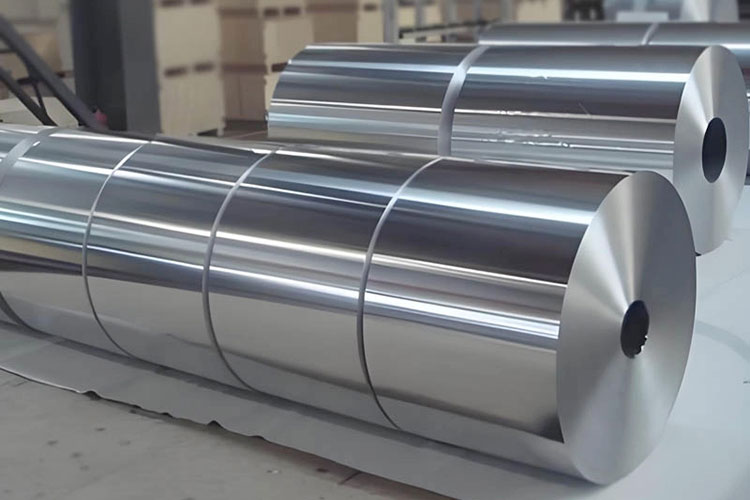

The aluminum ingots are first processed into aluminum foil jumbo rolls through cold rolling or hot rolling techniques. The thickness of the foil is strictly controlled between 0.03mm and 0.20mm, depending on the type of container (disposable or reusable, wrinkled or wrinkle-free). During rolling, the aluminum is pressed into uniform, smooth sheets with no pinholes, dust particles, or odors, ensuring the base material is clean and safe for subsequent processing.

2. Uncoiling and Lubrication

The aluminum foil jumbo rolls (with a diameter of up to 800mm and a core diameter of 76mm or 152mm) are placed on an automatic uncoiler, which feeds the foil into the production line stably. Before forming, the foil surface is coated with a food-grade lubricant—usually a water-based or environment-friendly oil—that serves multiple purposes: reducing friction between the foil and molds, preventing scratches, dissipating heat generated during stamping, and protecting the equipment and molds from wear. The lubricant consumption is precisely controlled at 300-600 mg per square meter to avoid residue on the final product.

3. Automatic Feeding and Precision Stamping

The lubricated aluminum foil is fed into a high-precision automatic stamping machine by a stepper motor, which ensures feeding accuracy within ±0.03mm. The stamping machine, equipped with a vertical pneumatic press (with a nominal force of 40-110 tons) and custom molds, uses cold stamping technology to shape the foil into the desired container form in one go.

The molds are processed using high-precision CNC and low-speed wire cutting techniques to guarantee the accuracy of the container’s shape, size, and edge smoothness. The stamping frequency ranges from 40 to 88 times per minute, enabling efficient mass production—an average production line can produce up to 20,000 containers per day. During stamping, the aluminum foil undergoes plastic deformation under pressure, forming the bottom, walls, and edges of the container (e.g., lunch boxes, trays, bowls) without breaking, thanks to the excellent ductility of the selected aluminum alloys.

4. Blanking and Scrap Recycling

After stamping, the formed containers are separated from the remaining aluminum foil (scrap) through a blanking process. The scrap is collected by an automatic scrap recycling system, compressed into blocks, and sent for recycling—aluminum foil can be recycled at a rate of over 95%, making the production process environmentally friendly and resource-efficient. This not only reduces waste but also lowers the overall production cost.

5. Cleaning, Drying and Post-Processing

The blanked containers are cleaned to remove any residual lubricant or dust, ensuring they meet food-grade hygiene standards. They are then dried thoroughly to prevent moisture accumulation, which could affect the container’s performance or cause contamination. For some special-purpose containers (e.g., those for high-temperature baking or long-term storage), a thin coating of polyester or polypropylene may be applied to enhance corrosion resistance and heat-sealing performance.

Additional post-processing steps may include trimming the edges to remove burrs, shaping the rims for better sealing, or printing simple logos (using food-safe inks) based on customer requirements.

6. Quality Inspection and Packaging

Quality control is a critical step throughout the manufacturing process. Finished containers are inspected for defects such as pinholes, scratches, uneven thickness, burrs, or poor forming. Advanced online visual inspection systems are used to check the edge integrity, bottom flatness, and size accuracy, ensuring a pass rate of over 99.2%. The containers are also tested for aluminum migration—ensuring the migration amount is between 0.15-0.32mg/kg, far below the national standard limit.

Qualified containers are then stacked automatically by a stacker (up to a height of 300mm) and packaged in cartons or plastic films, ready for delivery to customers. The packaging is designed to protect the containers from damage during transportation and storage.

In summary, the production of aluminum foil containers is a highly automated, precise, and environmentally friendly process. From raw material selection to final packaging, every step is strictly controlled to ensure the products are safe, durable, and suitable for a wide range of applications—from aviation food packaging to household baking and takeout services.