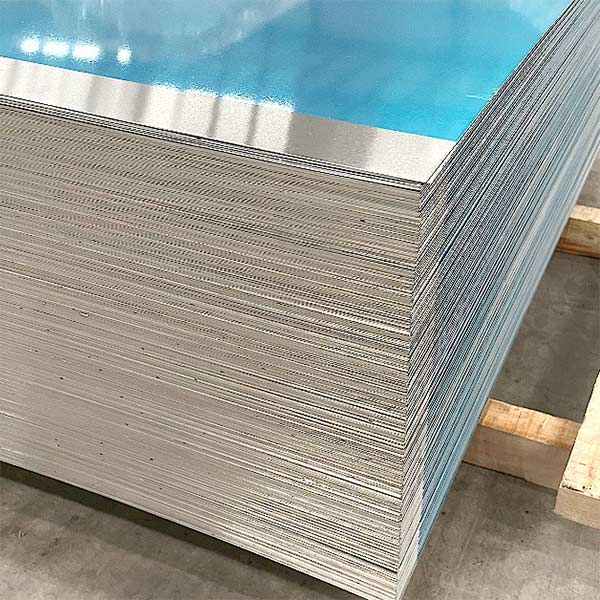

8011 aluminum sheet is a corrosion-resistant alloy known for its excellent formability and moderate strength. It is widely used in packaging and household applications, offering reliable performance in rolling, bending, and forming processes.

Description

Features

- Excellent Corrosion Resistance

Resistant to oxidation and environmental corrosion.

- Good Formability & Ductility

Easily cut, bent, and rolled without cracking.

- Lightweight & Durable

Ideal for applications requiring low weight and long service life.

- Non-Toxic & Safe

Suitable for food contact and household applications.

- Thermal & Electrical Conductivity

Adequate for heat transfer and electrical applications.

- Recyclable & Eco-Friendly

Fully recyclable with minimal environmental impact.

- Stable Mechanical Properties

Reliable performance for various industrial processes.

Specifications

| Item | Specification |

|---|---|

| Alloy | 8011 |

| Aluminum Content / Chemical Composition | Al: Balance, Fe: 0.6–1.2%, Si: 0.1–0.5%, Mn: 0.2–0.5%, Cu: ≤ 0.05%, Zn: ≤ 0.1%, Ti: ≤ 0.03%, Others: ≤ 0.05% |

| Temper | H14, H18, O (customized) |

| Thickness Range | 0.006 – 2.0 mm |

| Width Range | Up to 2,000 mm (customized) |

| Form | Coil, cut-to-length sheets |

| Surface Finish | Bright, smooth, or matt |

| Density | 2.70 g/cm³ |

| Tensile Strength | 70–140 MPa (depending on temper) |

| Elongation | 8–35% (depending on temper) |

Applications

- Household aluminum foil.

- Food packaging and containers.

- Beverage can stock.

- Industrial wrapping and insulation sheets.