6082 aluminum sheet is a heat-treatable aluminum alloy belonging to the Al-Mg-Si (6xxx) series. It is known for its high strength within the 6xxx series, excellent corrosion resistance, and good machinability. Compared with 6061, 6082 offers higher mechanical strength, making it a preferred choice for structural and load-bearing applications in transportation, marine, and industrial fields.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 6082 |

| Chemical Composition (%) | Mg 0.6–1.2, Si 0.7–1.3, Mn 0.4–1.0, Fe ≤ 0.50, Cu ≤ 0.10, Cr ≤ 0.25, Zn ≤ 0.20, Ti ≤ 0.10, Al Balance |

| Series | 6000 Series (Al-Mg-Si) |

| Temper | O, T4, T6, T651 |

| Thickness (mm) | 0.5 – 150 |

| Width (mm) | 100 – 2600 |

| Length (mm) | 1000 – 12000 (Customizable) |

| Surface Finish | Mill Finish, Anodized (Optional) |

| Standard | ASTM B209, EN AW-6082, GB/T 3880 |

Description

Features

- High mechanical strength

Suitable for structural, automotive, transportation, and construction applications requiring medium-to-high strength.

- Excellent corrosion resistance

Performs well in atmospheric, marine, and industrial environments; corrosion resistance can be further enhanced by anodizing or coating.

- Excellent formability and workability

Can be rolled, bent, stamped, and extruded, suitable for medium-to-thin gauge sheets and moderate-to-complex forming processes.

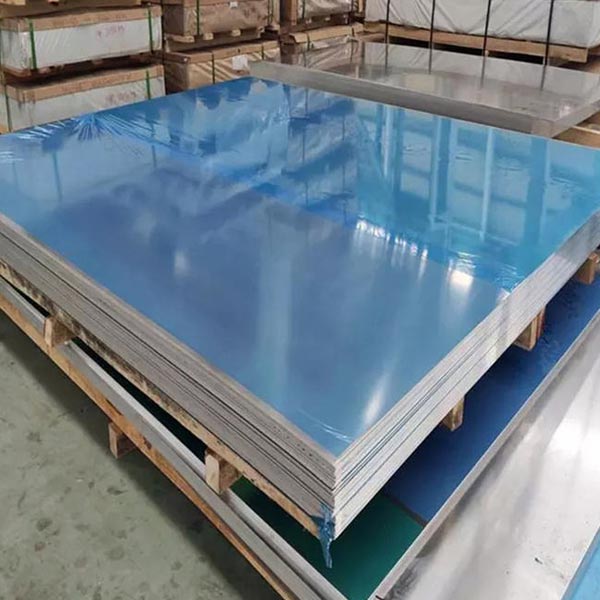

- Smooth and uniform surface finish

Ideal for anodizing, painting, coating, or film lamination for both decorative and functional purposes.

- Good weldability

Compatible with TIG, MIG, and spot welding; post-weld heat treatment can optimize mechanical performance.

- Lightweight material

Low density helps reduce overall weight while maintaining structural performance.

Applications

- Structural components and frames.

- Truck bodies, trailers, and chassis parts.

- Marine and offshore structures.

- Bridges and construction structures.

- Industrial machinery and equipment.