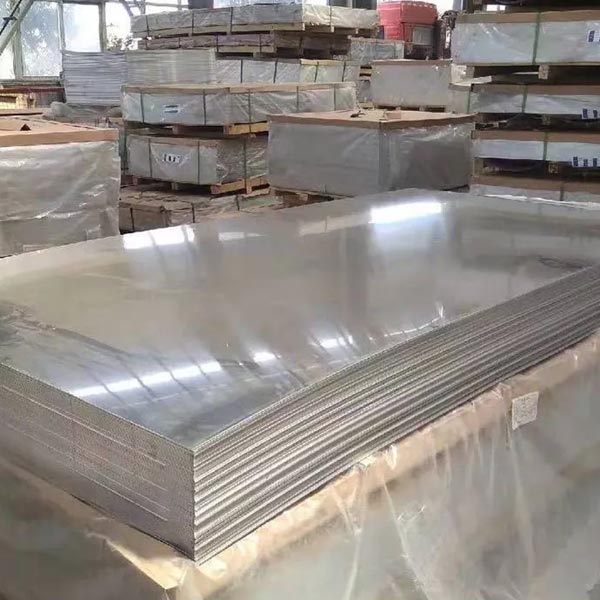

6060 aluminum sheet is a heat-treatable aluminum alloy belonging to the Al-Mg-Si (6xxx) series. It is known for its excellent formability, good surface quality, and reliable corrosion resistance. Compared with 6061 and 6082, 6060 offers lower strength but superior extrudability and finishing performance, making it especially suitable for architectural and decorative applications where appearance is important.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 6060 |

| Chemical Composition (%) | Mg 0.35–0.60, Si 0.30–0.60, Fe ≤ 0.30, Cu ≤ 0.10, Mn ≤ 0.10, Cr ≤ 0.05, Zn ≤ 0.15, Ti ≤ 0.10, Al Balance |

| Series | 6000 Series (Al-Mg-Si) |

| Temper | O, T4, T5, T6 |

| Thickness (mm) | 0.5 – 120 |

| Width (mm) | 100 – 2600 |

| Length (mm) | 1000 – 12000 (Customizable) |

| Surface Finish | Mill Finish, Anodized, Polished, Painted |

| Standard | ASTM B209, EN AW-6060, GB/T 3880 |

Description

Features

- Medium mechanical strength

Suitable for architectural, structural, and automotive applications requiring moderate strength.

- Excellent corrosion resistance

Performs well in atmospheric, marine, and industrial environments; corrosion resistance can be further enhanced by anodizing or coating.

- Excellent formability and workability

Can be rolled, bent, stamped, and extruded, suitable for medium-to-thin gauge sheets and moderate forming processes.

- Smooth and uniform surface finish

Ideal for anodizing, painting, coating, or film lamination for both decorative and functional purposes.

- Good weldability

Compatible with TIG, MIG, and spot welding; post-weld heat treatment can optimize mechanical performance.

- Lightweight material

Low density helps reduce overall weight while maintaining structural performance.

Applications

- Architectural panels and decorative sheets.

- Doors, windows, and curtain wall systems.

- Interior decoration and furniture components.

- Lightweight structural parts.

- General industrial applications.