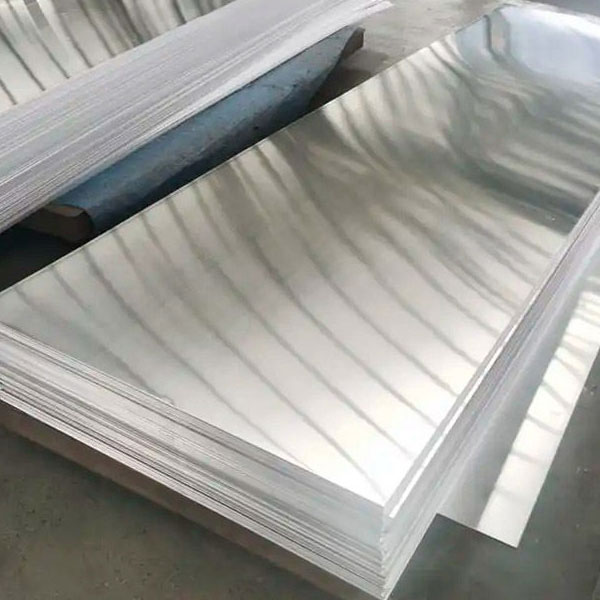

6016 aluminum sheet is a heat-treatable aluminum alloy in the Al-Mg-Si (6xxx) series, widely used in the automotive industry. It is particularly valued for its excellent formability in the solution-treated condition and its ability to achieve high strength after paint-bake heat treatment. This makes 6016 aluminum sheet an ideal material for lightweight automotive body panels.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 6016 |

| Chemical Composition (%) | Mg 0.25–0.60, Si 1.0–1.5, Fe ≤ 0.50, Cu ≤ 0.20, Mn ≤ 0.20, Cr ≤ 0.10, Zn ≤ 0.25, Ti ≤ 0.15, Al Balance |

| Series | 6000 Series (Al-Mg-Si) |

| Temper | T4, T6 |

| Thickness (mm) | 0.5 – 6.0 |

| Width (mm) | 600 – 2000 |

| Length (mm) | 1000 – 6000 (Customizable) |

| Surface Finish | Mill Finish, Pre-treated, Oiled |

| Standard | ASTM B209, EN 573, EN 485 |

Description

Features

- Good mechanical strength

Suitable for automotive body panels, transportation parts, and structural applications requiring medium-to-high strength.

- Excellent corrosion resistance

Performs well in atmospheric, marine, and industrial environments; corrosion resistance can be enhanced by anodizing or coating.

- Excellent formability and workability

Can be rolled, bent, stamped, and extruded, suitable for medium-to-thin gauge sheets and moderate forming processes.

- Smooth and uniform surface finish

Ideal for anodizing, painting, coating, or film lamination for both decorative and functional purposes.

- Good weldability

Compatible with TIG, MIG, and spot welding; post-weld heat treatment can optimize mechanical performance.

- Lightweight material

Low density helps reduce overall weight while maintaining structural performance.

Applications

- Automotive outer and inner body panels.

- Car doors, hoods, roofs, and fenders.

- Lightweight vehicle structures.

- Transportation body panels.