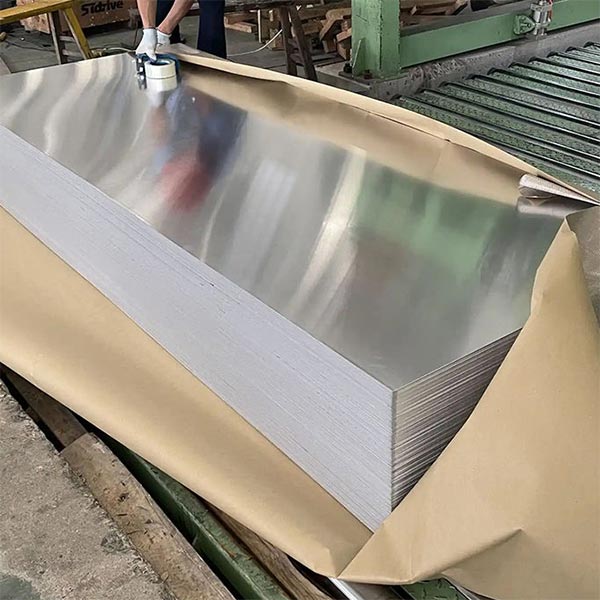

2A11 aluminum sheet is a heat-treatable aluminum–copper–magnesium alloy in the 2xxx series. It offers high strength, good fatigue resistance, and excellent machinability, and is widely used in aerospace, aviation, and mechanical manufacturing industries. 2A11 is similar to 2024 aluminum alloy in performance and is often selected for structural components requiring high strength and reliability.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 2A11 |

| Chemical Composition (%) | Cu 3.8–4.9, Mg 1.2–1.8, Mn 0.3–0.9, Fe ≤ 0.50, Si ≤ 0.50, Zn ≤ 0.30, Ti ≤ 0.15, Al Balance |

| Series | 2000 Series (Al-Cu-Mg) |

| Temper | O, T4, T6 |

| Thickness (mm) | 0.5 – 200 |

| Width (mm) | 100 – 2600 |

| Length (mm) | 2000 – 6000 |

| Surface Finish | Mill Finish, Alclad, Anodized, Painted |

| Standard | GB/T 3880, ASTM B209 (Equivalent to 2024) |

Description

Features

- High Mechanical Strength

Provides high strength after heat treatment, suitable for load-bearing and structural applications.

- Good Fatigue Resistance

Maintains stable performance under repeated stress and vibration, making it suitable for dynamic and cyclic loading conditions.

- Excellent Machinability

Easy to machine, drill, and mill with good dimensional accuracy and surface quality.

- Heat Treatable Alloy

Mechanical properties can be significantly enhanced through solution heat treatment and artificial aging.

- Mature and Reliable Alloy

A well-established alloy widely used in aerospace and industrial applications with proven long-term performance.

Applications

- Aircraft and aerospace structural components.

- Aviation fittings and connectors.

- High-strength mechanical parts.

- Military and defense equipment.

- Precision engineering components.