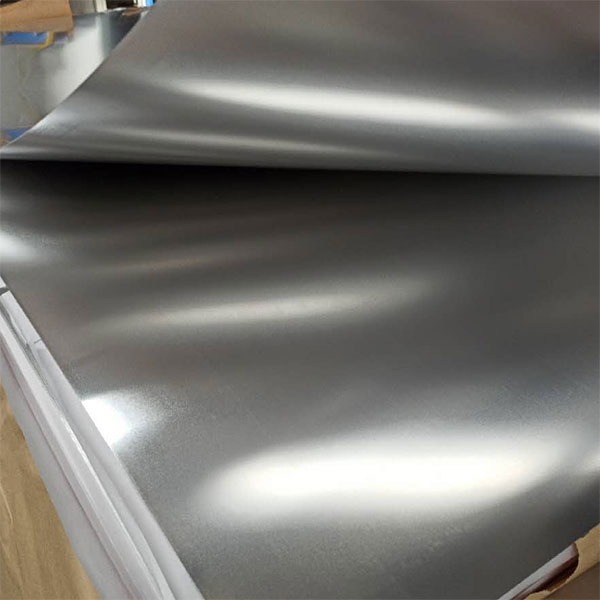

1350 aluminum sheet is a high-purity aluminum in the 1000 series, with an aluminum content of 99.5% or higher. It is widely used in electrical, chemical, and construction applications due to its excellent corrosion resistance, superior conductivity, and good formability. 1350 aluminum sheet is often applied where high electrical conductivity and chemical stability are required.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 1350 |

| Chemical Composition (%) | Al ≥ 99.5, Fe ≤ 0.30, Si ≤ 0.25, Cu ≤ 0.05, Mn ≤ 0.03, Mg ≤ 0.03, Zn ≤ 0.10, Ti ≤ 0.03, Others ≤ 0.05 |

| Series | 1000 Series (Pure Aluminum) |

| Temper | O, H14, H16, H18, H19, H22 |

| Thickness (mm) | 0.1 – 250 |

| Width (mm) | 100 – 2650 |

| Length (mm) | 2000 – 6000 |

| Surface Finish | Mill Finish, Anodized, Polished |

| Standard | ASTM B209, EN AW-1350, GB/T 3880 |

Description

Features

- Excellent Corrosion Resistance

Maintains long-term stability and durability in atmospheric and chemical environments.

- High Purity and Conductivity

Contains 99.5% or higher aluminum, providing excellent electrical and thermal conductivity.

- Good Formability

Can be easily bent, rolled, or fabricated, suitable for panels, electrical components, and decorative applications.

- Easy to Weld and Fabricate

Supports welding and machining processes with minimal risk of cracking or distortion.

- Chemical Stability and Safety

Non-toxic and chemically stable, safe for electrical and industrial applications.

Applications

- Electrical and electronic components requiring high conductivity.

- Chemical equipment and storage tanks.

- Architectural and decorative panels.

- Industrial machinery.

- Packaging materials and non-structural components.