1050 Aluminum Sheet belongs to the 1000 series of industrial pure aluminum, with an aluminum content of no less than 99.5%. It is widely used in applications that require excellent corrosion resistance, high electrical and thermal conductivity, and good formability. Due to its stable performance and cost efficiency, 1050 aluminum sheet is one of the most commonly used pure aluminum materials.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 1050 |

| Chemical Composition (%) | Al ≥ 99.50, Si ≤ 0.25, Fe ≤ 0.40, Cu ≤ 0.05, Mn ≤ 0.05, Mg ≤ 0.05, Zn ≤ 0.05, Ti ≤ 0.03, Others ≤ 0.15 |

| Series | 1000 Series (Pure Aluminum) |

| Temper | O, H12, H14, H16, H18, H22, H24 |

| Thickness (mm) | 0.2 – 200 |

| Width (mm) | 100 – 2600 |

| Length (mm) | 2000 – 6000 |

| Surface Finish | Mill Finish, Brushed, Polished, Anodized |

| Standard | ASTM B209, EN AW-1050A, GB/T 3880 |

Description

Features

- High-purity aluminum (Al ≥ 99.5%)

Belongs to the 1000-series aluminum alloys, offering stable chemical composition and consistent material performance.

- Excellent corrosion resistance

Forms a natural and dense oxide layer, providing reliable resistance to atmospheric corrosion and humid environments.

- Good electrical and thermal conductivity

Suitable for applications requiring efficient electrical transmission and heat dissipation.

- Excellent formability and workability

Soft and ductile material, easy to process by bending, stamping, stretching, rolling, and deep drawing.

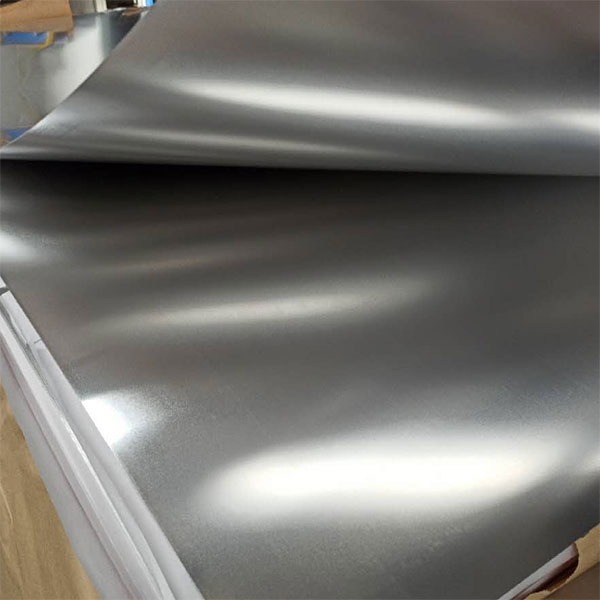

- Smooth and uniform surface quality

Provides an excellent base for anodizing, painting, coating, embossing, or film lamination.

- Good weldability

Compatible with common aluminum welding methods such as TIG and MIG, ensuring reliable joints.

- Lightweight material

Low density helps reduce overall weight while maintaining good durability.

Applications

- Architectural and building applications

Used for roofing, wall cladding, ceiling panels, and decorative sheets due to good corrosion resistance and surface quality.

- Electrical applications

Suitable for electrical bus bars, conductor plates, transformer components, and electrical enclosures because of good electrical conductivity.

- Heat transfer and thermal applications

Applied in heat exchangers, heat shields, and insulation panels requiring good thermal conductivity.

- Chemical and industrial equipment

Used for tanks, liners, covers, and containers in mild chemical environments due to its corrosion resistance.

- Signage and decorative products

Commonly used for nameplates, signboards, reflectors, and decorative panels with surface treatment.

- General fabrication and forming

Suitable for stamping, bending, deep drawing, and forming of non-structural components.