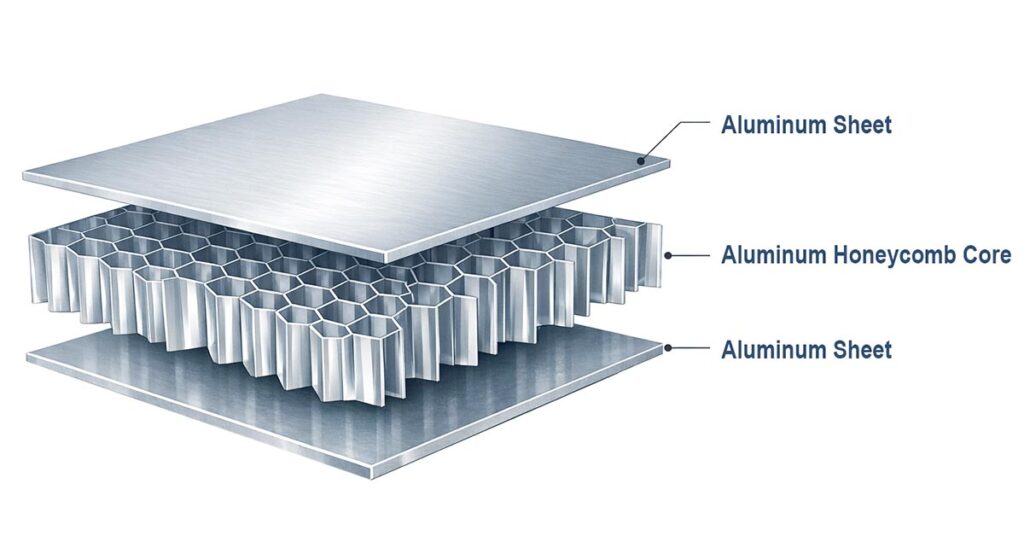

The core material of aluminum honeycomb panels is made of aluminum foil processed into a hexagonal grid structure, which is key to the panel’s lightweight and high strength. The hexagonal biomimetic structure of the honeycomb core mimics the geometry of a natural honeycomb, evenly distributing external forces, avoiding localized stress concentration, and maximizing the material’s strength-to-weight ratio. It possesses excellent compressive and shear strength, and the closed air cavities within the grid effectively block the transfer of heat and sound waves.

Description

Aluminum Honeycomb Panel Structure

Features of Aluminum Honeycomb

- Lightweight and High-Strength

The honeycomb structure combined with high-strength aluminum foil significantly reduces material density while improving compressive and bending resistance.

- Excellent Corrosion and Weather Resistance

Aluminum alloys inherently possess good oxidation resistance, which can be further enhanced through surface treatment.

- Thermal and Acoustic Insulation

The closed air layers in the hexagonal honeycomb effectively block heat conduction and sound propagation, making it suitable for indoor thermoacoustic optimization.

- High-Temperature Stability

It can withstand high temperatures without failure during the sandwich hot-pressing process.

Specifications

| Parameter | Range | Remarks |

|---|---|---|

| Thickness | 0.02–0.08 mm | 0.04–0.06 mm is standard for most industrial applications |

| Width | 80–1800 mm | 3004 alloy foil is primarily supplied in 100–1600 mm widths |

| Length | Custom | Cut-to-length or coil form available per production line requirements |

| Honeycomb Core Size | 3–19 mm | Side length of the hexagonal cell; dictates compressive strength |

| Surface Treatment | Mill Finish, Anodizing, Coating, Oxidation | Enhances adhesion for lamination and corrosion resistance |

Main Alloy Grades and Applications

| Alloy Grade | Core Characteristics | Application Scenario |

|---|---|---|

| 1100/3003 | Good formability, low cost | General civil applications (ordinary building decoration, low-demand home appliance parts) |

| 3004 | Optimal comprehensive performance, light weight, high strength, excellent weather resistance and corrosion resistance | Mainstream application (architectural curtain walls, transportation, aerospace core components) |

| 8011 | Good processability and thermal insulation | Packaging, low-load thermal insulation components |

| 5052 | High strength and corrosion resistance | High-end precision fields (aerospace key parts, marine equipment) with small usage due to high cost |

Production Process of Aluminum Honeycomb Core

The production of aluminum honeycomb core material is a precise, multi-stage process, with the core objective of ensuring its structural integrity and performance stability.

- Raw Material Preparation

Aluminum foil is cut and shaped into aluminum foil blanks of specified specifications to ensure uniformity in thickness and dimensions.

- Surface Treatment

First, the aluminum foil blanks are degreased with an acidic solution to remove surface oil; then, deoxidation treatment is performed to remove surface oxides, ensuring the purity of the aluminum foil surface and its adhesion properties.

- Core Forming and Fixing

The treated aluminum foil is placed on specialized equipment and pressed and stretched to form a flat hexagonal honeycomb core material. Pressure and temperature are controlled to ensure the flatness and firmness of the core material.