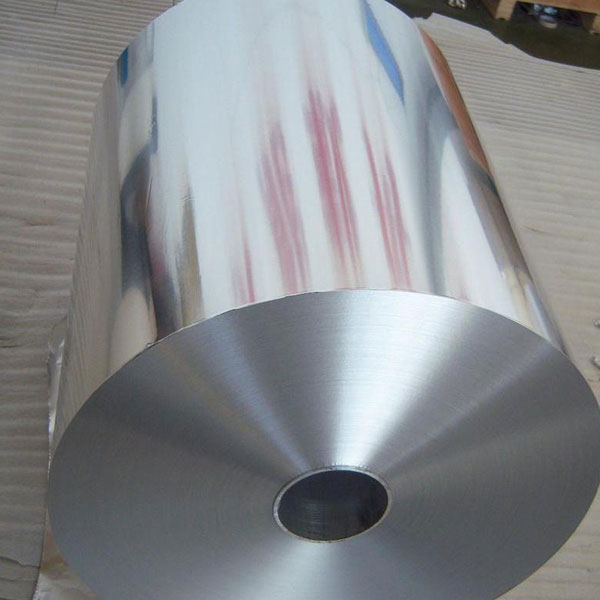

3003 aluminum foil is an alloy of aluminum known for its versatility, durability, and excellent corrosion resistance. It is one of the most commonly used alloys in the aluminum foil industry, offering a balance of strength, flexibility, and performance in a wide range of applications.

Technical Specifications

| Parameter | Description |

|---|---|

| Alloy | 3003 |

| Chemical Composition (%) | Al ≥ 98.0, Mn 1.0-1.5, Fe ≤ 0.7, Cu ≤ 0.05, Si ≤ 0.6, Zn ≤ 0.1, Ti ≤ 0.15, Others ≤ 0.05 |

| Temper | O (Soft), H14, H18 |

| Thickness Range | 6 – 100 μm (commonly 9 / 12 / 15 μm) |

| Width | Customizable |

| Surface Finish | Bright / Matte / Coated |

Description

Features

- Corrosion Resistance

3003 aluminum foil has excellent resistance to atmospheric corrosion, especially in outdoor and marine environments, making it suitable for various weather conditions.

- Good Formability

This alloy can be easily shaped or formed into different sizes and designs, allowing it to be used in flexible packaging, insulation, and other applications that require malleability.

- Strength

While it is not as strong as other alloys like 6061, 3003 offers a good strength-to-weight ratio for many applications. It’s stronger than pure aluminum (1070).

- Weldability

3003 is known for its good weldability, making it an excellent choice for applications that require joining with other materials.

- Printable

Its surface can be printed on, making it suitable for customized packaging and labeling.

Common Applications

- Food Packaging

3003 aluminum foil is commonly used in food packaging, as it protects food from moisture, light, and contaminants. It’s used in wrapping, cooking, and storage.

- Insulation

Due to its reflective properties, 3003 aluminum foil is widely used in insulation applications, especially in buildings and refrigeration.

- Pharmaceutical Packaging

Like other aluminum foils, it is used for blister packaging to protect pharmaceuticals from moisture and air.

- Electrical

3003 is used for cable shields and insulation materials due to its electrical conductivity.

- Heat Exchangers

The alloy is suitable for use in heat exchangers because of its thermal conductivity and corrosion resistance.