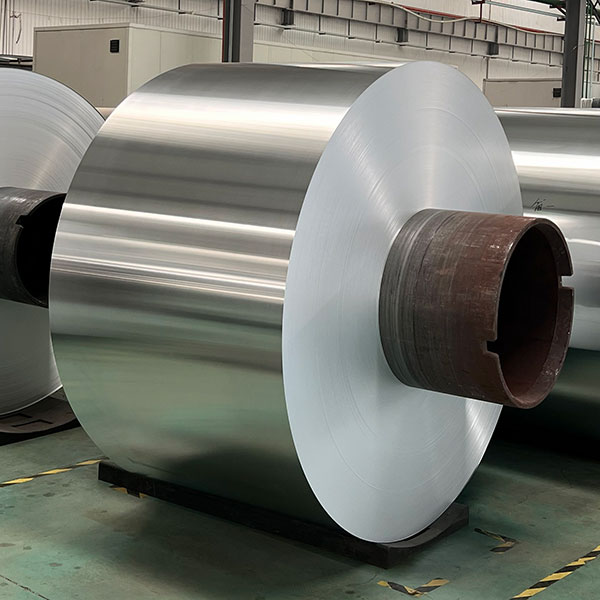

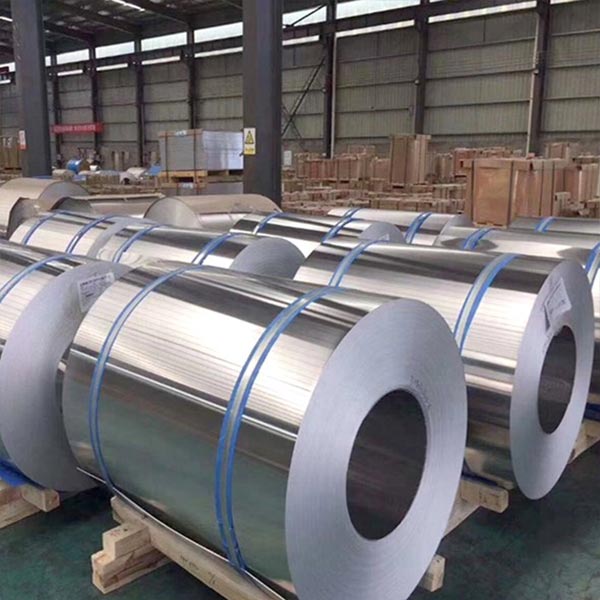

8021 aluminum coil is a non-heat-treatable aluminum alloy belonging to the 8xxx series, alloyed mainly with iron (Fe) and silicon (Si). It is well known for its excellent barrier properties, good strength, and superior formability. Due to its clean surface quality and stable performance, 8021 aluminum coil is widely used in pharmaceutical packaging, food packaging, battery packaging, and laminated foil applications.

Specifications

| Item | Specification |

|---|---|

| Alloy | 8021 |

| Chemical Composition (%) | Al: Balance; Fe: 1.2–1.8; Si: ≤ 0.20; Cu: ≤ 0.05; Mn: ≤ 0.10; Mg: ≤ 0.05; Zn: ≤ 0.10; Ti: ≤ 0.05; Others: ≤ 0.15 |

| Temper | O, H14, H16, H18, H22, H24 |

| Thickness | 0.02 – 2.5 mm |

| Width | 100 – 2000 mm |

| Inner Diameter | 76 mm / 152 mm / 300 mm |

| Coil Weight | 1 – 5 tons (customizable) |

| Surface Finish | Mill finish, one side bright, both sides bright |

| Standards | ASTM, EN, GB/T, JIS |

Description

Features

- High barrier performance

Effectively blocks moisture, oxygen, light, and odors, ensuring long-term protection for sensitive products.

- Excellent formability

Suitable for rolling, slitting, stamping, and deep drawing, enabling stable performance in high-speed production lines.

- Good mechanical strength

Provides higher strength than pure aluminum while maintaining good flexibility and processing stability.

- Superior corrosion resistance

Resists oxidation and corrosion, ensuring long service life in various environmental conditions.

- Clean surface quality

Low pinhole rate and uniform surface finish, ideal for pharmaceutical and high-end packaging applications.

- Food-grade safety

Non-toxic and odorless, compliant with food-contact and pharmaceutical packaging standards.

Applications

- Food packaging

Widely used for aluminum foil in food wrapping, containers, trays, and pouches due to excellent corrosion resistance, hygiene, and barrier properties.

- Household applications

Suitable for kitchen foil, baking sheets, and disposable containers.

- Industrial packaging

Applied in pharmaceutical, cosmetic, and chemical packaging where hygiene, corrosion resistance, and barrier properties are important.

- Heat transfer applications

Ideal for components requiring good thermal conductivity, such as heat exchangers or thermal packaging.

- Electrical applications

Can be used for capacitors, shielding, and other thin-gauge electrical components.

- Decorative and functional laminates

Suitable for coating, printing, or laminating for functional or decorative purposes.