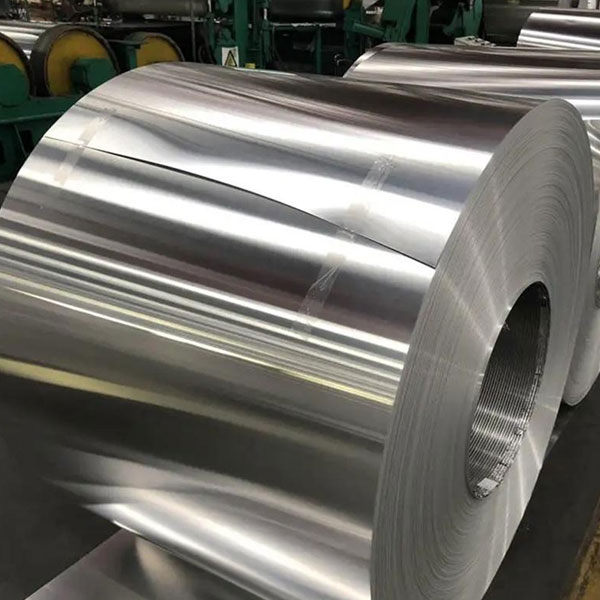

7075 aluminum coil is a high-strength, heat-treatable aluminum alloy from the Al-Zn-Mg-Cu (7xxx) series. It is one of the strongest aluminum alloys available, offering an exceptional strength-to-weight ratio and excellent fatigue resistance. Due to its outstanding mechanical performance, 7075 aluminum sheet is widely used in aerospace, defense, and high-performance structural applications where maximum strength is required.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 7075 |

| Chemical Composition (%) | Zn 5.6–6.1, Mg 2.1–2.5, Cu 1.2–1.6, Cr 0.18–0.28, Fe ≤ 0.50, Si ≤ 0.40, Mn ≤ 0.30, Ti ≤ 0.20, Al Balance |

| Series | 7000 Series (Al-Zn-Mg-Cu) |

| Temper | O, T6, T651, T73, T7351 |

| Thickness (mm) | 1.0 – 150 |

| Width (mm) | 100 – 2600 |

| Length (mm) | 1000 – 12000 (Customizable) |

| Surface Finish | Mill Finish, Anodized (Optional) |

| Standard | ASTM B209, AMS 4045 / 4049, EN AW-7075, GB/T 3880 |

Description

Features

- Ultra-High Strength

Provides extremely high tensile and yield strength after heat treatment, comparable to some steels while maintaining low weight.

- Excellent Fatigue Resistance

Performs reliably under cyclic and high-stress loading, ideal for aerospace and dynamic structural components.

- Good Machinability

Well-suited for precision machining, producing stable dimensions and high-quality finished parts.

- Good Fracture Toughness

Maintains structural integrity under high loads, reducing the risk of sudden failure.

- Heat-Treatable Performance

Mechanical properties can be optimized through solution treatment and aging.

Applications

- Aerospace and aviation components

Widely used in aircraft fuselage, wings, landing gear, and other critical structural components due to very high strength and excellent fatigue resistance.

- Military and defense applications

Suitable for armored vehicles, military aircraft, missile components, and other high-strength defense structures.

- Transportation and automotive parts

Applied in high-load structural parts of trucks, buses, and high-performance vehicles where strength-to-weight ratio is critical.

- Structural engineering

Used for bridges, cranes, and other load-bearing structures requiring high mechanical strength and lightweight material.

- Marine applications

Suitable for ship and boat structures where high strength and moderate corrosion resistance are required.

- General fabrication and forming

Ideal for rolling, stamping, bending, and extrusion of medium-to-thin gauge sheets for structural or functional purposes.