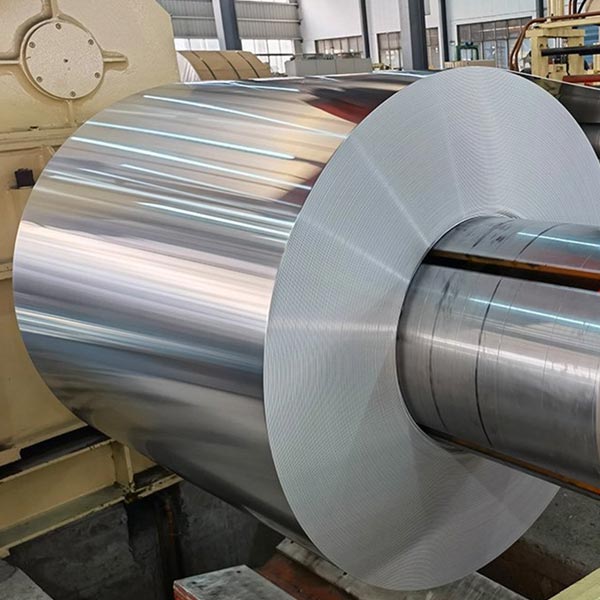

6082 aluminum coil belongs to the 6000 series aluminum-magnesium-silicon alloy, with magnesium (Mg) content of approximately 0.6 – 1.2%, silicon (Si) 0.7 – 1.3%, and aluminum content ≥ 95.8%. This alloy features high strength, excellent corrosion resistance, good mechanical properties, and good weldability, making it especially suitable for aerospace, transportation, mechanical manufacturing, construction structures, and industrial equipment. 6082 Aluminum Coil can be heat-treated for strengthening and is suitable for structural components that require high strength and complex load-bearing.

Specifications

| Parameter | Description |

|---|---|

| Alloy | 6082 |

| Chemical Composition (%) | Al ≥ 95.8, Mg 0.6 – 1.2, Si 0.7 – 1.3, Cu 0.0 – 0.4, Fe ≤ 0.5, Mn 0.4 – 1.0, Cr 0.0 – 0.25, Zn ≤ 0.2, Ti ≤ 0.1, Others ≤ 0.15 |

| Temper | O (Soft), T4, T6, T651 |

| Thickness Range | 0.5 – 6.0 mm (customizable) |

| Width | Customizable (20 – 2000 mm) |

| Coil Weight | Customizable |

| Inner Diameter (ID) | 150 / 300 / 505 mm |

| Surface Finish | Mill Finish, Bright, Brushed, Coated, Film Laminated (optional) |

| Standard | ASTM B209 / EN AW-6082 / GB/T 3190 |

Description

Features

- Magnesium–silicon aluminum alloy

Belongs to the 6000-series aluminum alloys, with Mg and Si as the primary alloying elements, offering higher strength than 6061 in many applications.

- High mechanical strength

One of the strongest alloys in the 6000 series, suitable for structural and load-bearing applications.

- Good corrosion resistance

Provides reliable resistance to atmospheric corrosion and industrial environments, suitable for outdoor and marine-adjacent applications.

- Good thermal conductivity

Supports effective heat dissipation in mechanical and structural components.

- Good machinability

Suitable for cutting, drilling, milling, and CNC machining, ideal for precision structural parts.

- Good formability

Can be formed in soft tempers and then heat treated (such as T6) to achieve high strength after fabrication.

- Good weldability

Compatible with TIG and MIG welding, with stable joint performance after proper process control.

- Good surface treatment performance

Suitable for anodizing, painting, and coating, providing a uniform and durable surface finish.

Applications

- Aerospace & Transportation

Aircraft components, automotive panels, ship structures.

- Mechanical Manufacturing

Machine frames, load-bearing structural components, industrial equipment.

- Construction Structures

Curtain walls, roofing panels, ceilings.

- Industrial Equipment

Pressure vessels, storage tanks, heat exchangers.

- Other

High-strength load-bearing parts, structural components.