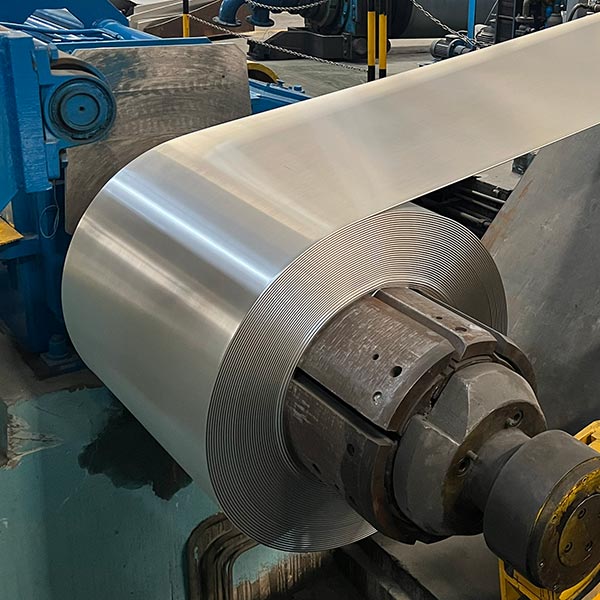

5754 aluminum coil is a non-heat-treatable aluminum-magnesium alloy in the 5xxx series. It is widely used for excellent corrosion resistance, moderate strength, and good weldability. 5754 alloy is suitable for marine, transportation, chemical, and architectural applications, particularly in environments exposed to seawater, moisture, or industrial atmospheres.

Specifications

| Item | Specification |

|---|---|

| Alloy / Grade | 5754 |

| Chemical Composition (%) | Mg 3.0–3.7, Mn 0.30–0.60, Cr 0.20–0.50, Fe ≤ 0.40, Si ≤ 0.25, Cu ≤ 0.10, Zn ≤ 0.25, Ti ≤ 0.15, Al Balance |

| Series | 5000 Series (Al-Mg) |

| Temper | O, H12, H14, H16, H22 |

| Thickness (mm) | 0.5 – 250 |

| Width (mm) | 100 – 2650 |

| Length (mm) | 1000 – 12000 (Customizable) |

| Surface Finish | Mill Finish, Anodized, Painted, Polished |

| Standard | ASTM B209, EN AW-5754, GB/T 3880 |

Description

Features

- Superior corrosion resistance

Performs exceptionally well in marine, chemical, and industrial environments, ideal for outdoor, coastal, and marine applications.

- High mechanical strength

Stronger than 5005 and 5052, suitable for structural, load-bearing, and marine applications.

- Good formability and workability

Can be rolled, bent, stamped, and deep-drawn, suitable for medium-to-thin gauge processing and complex shapes.

- Good thermal and electrical conductivity

Supports heat dissipation and moderate electrical applications.

- Smooth and uniform surface finish

Ideal for anodizing, painting, coating, embossing, or film lamination for both decorative and functional purposes.

- Excellent weldability

Compatible with TIG, MIG, and spot welding, ensuring reliable fabrication.

- Lightweight material

Low density helps reduce overall weight while maintaining strength and durability.

Applications

- Marine and shipbuilding applications

Widely used for hulls, decks, superstructures, and marine fittings due to superior corrosion resistance in seawater environments.

- Automotive and transportation parts

Suitable for truck panels, bus bodies, trailers, and structural components where high strength and corrosion resistance are required.

- Chemical and industrial equipment

Applied in tanks, containers, pressure vessels, and protective panels for chemical and industrial environments.

- Architectural and building applications

Used for roofing, curtain walls, cladding, and decorative panels in outdoor and coastal environments.

- Heat transfer and thermal applications

Suitable for heat exchangers, cooling fins, and other components requiring good thermal conductivity.

- General fabrication and forming

Ideal for stamping, bending, rolling, and deep-drawing of medium-to-thin gauge sheets for structural or decorative purposes.