1145 aluminum sheet belongs to the 1000 series of commercially pure aluminum, with an aluminum content of no less than 99.45%. It offers excellent corrosion resistance, formability, and electrical conductivity, making it a reliable and economical choice for applications requiring good purity and stable performance.

Specifications

| Parameter | Description |

|---|---|

| Alloy | 1145 |

| Chemical Composition (%) | Al ≥ 99.45, Si ≤ 0.55, Fe ≤ 0.55, Cu ≤ 0.10, Mn ≤ 0.05, Mg ≤ 0.05, Zn ≤ 0.10, Ti ≤ 0.03, Others ≤ 0.05 |

| Temper | O, H12, H14, H16, H18 |

| Thickness Range | 0.2 – 6.0 mm (customizable) |

| Width (mm) | 20 – 2000 |

| Length (mm) | 2000 – 6000 |

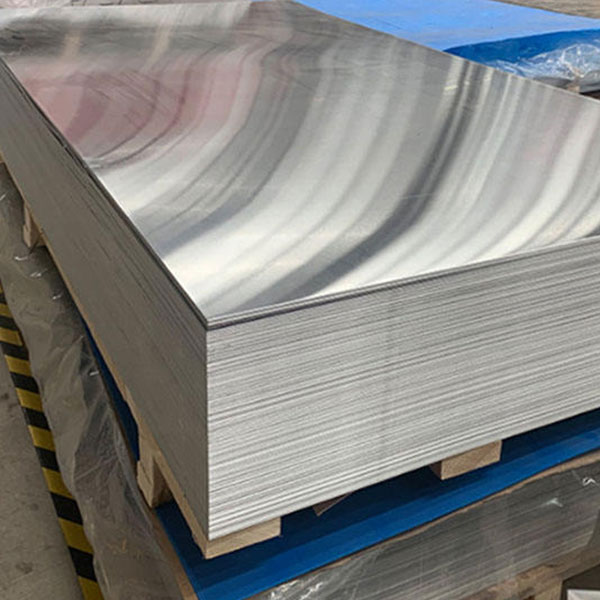

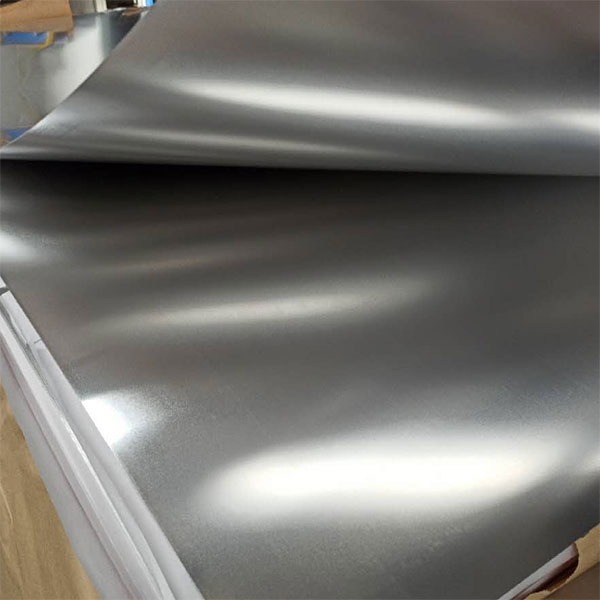

| Surface Finish | Mill Finish, Bright, Brushed, Coated, Film Laminated (optional) |

| Standard | ASTM B209 / EN AW-1145 / GB/T 3880 |

Description

Features

- High Aluminum Purity (≥ 99.45%)

Ensures good chemical stability and consistent material quality.

- Excellent Corrosion Resistance

Suitable for various indoor and outdoor environments.

- Good Electrical & Thermal Conductivity

Ideal for electrical and heat transfer applications.

- Very Good Formability

Suitable for bending, stamping, rolling, and general forming processes.

- Excellent Weldability

Compatible with conventional welding methods.

- Good Surface Finishing Performance

Suitable for anodizing, coating, polishing, and brushing.

Typical Applications

- Electrical conductors and components.

- Heat exchangers and thermal equipment.

- Architectural decoration and panels.

- Signboards and advertising materials.

- Industrial containers and general fabrication.