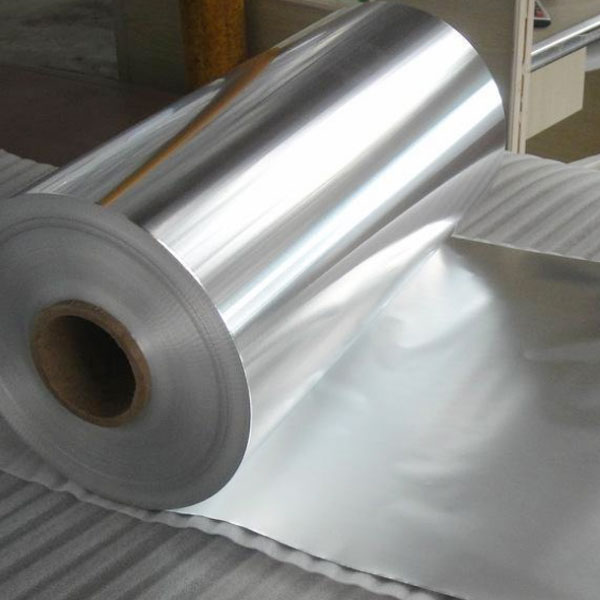

- Aluminum Foils

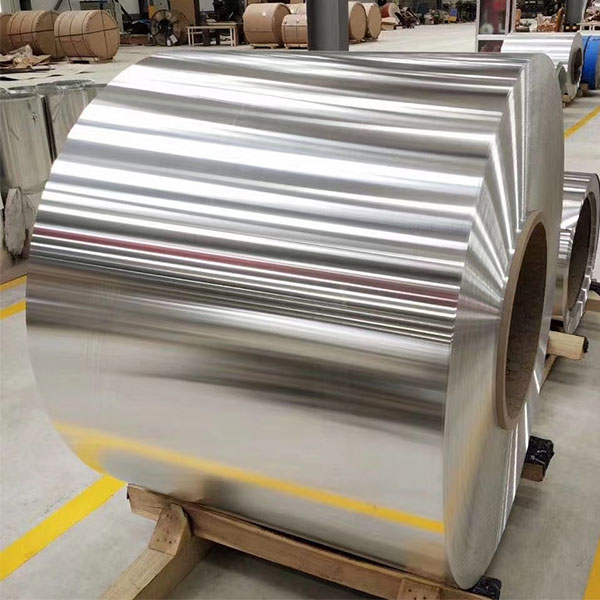

- Aluminum Coils

- Aluminum Sheets

- 1000 Series

- 2000 Series

- 3000 Series

- 5000 Series

- 5A02 Aluminum Sheet

- 5A03 Aluminum Sheet

- 5A05 Aluminum Sheet

- 5A06 Aluminum Sheet

- 5M52 Aluminum Sheet

- 5005 Aluminum Sheet

- 5052 Aluminum Sheet

- 5052A Aluminum Sheet

- 5052B Aluminum Sheet

- 5059 Aluminum Sheet

- 5056 Aluminum Sheet

- 5083 Aluminum Sheet

- 5086 Aluminum Sheet

- 5182 Aluminum Sheet

- 5454 Aluminum Sheet

- 5754 Aluminum Sheet

- 6000 Series

- 7000 Series

- Customization

- Applications

- Industry Applications

- News

- Contact Us

1000 Series Aluminum Foil

Home » Aluminum Foils » 1000 Series Aluminum Foil