Aluminium finstock plays a critical role in improving the energy efficiency, durability, and reliability of modern heat exchange systems. Finstock foil is a high-precision rolled aluminum material specially developed for manufacturing fins used in heat exchangers. A single coil of thin aluminum foil becomes thousands of high-efficiency fins after forming.

It is widely applied in air conditioners, automotive radiators, condensers, evaporators, refrigeration systems, and industrial cooling equipment. Engineered for excellent formability and thermal performance, finstock ensures stable fin forming during high-speed stamping while delivering efficient heat transfer.

How Aluminum Foil for Heat Exchangers Works

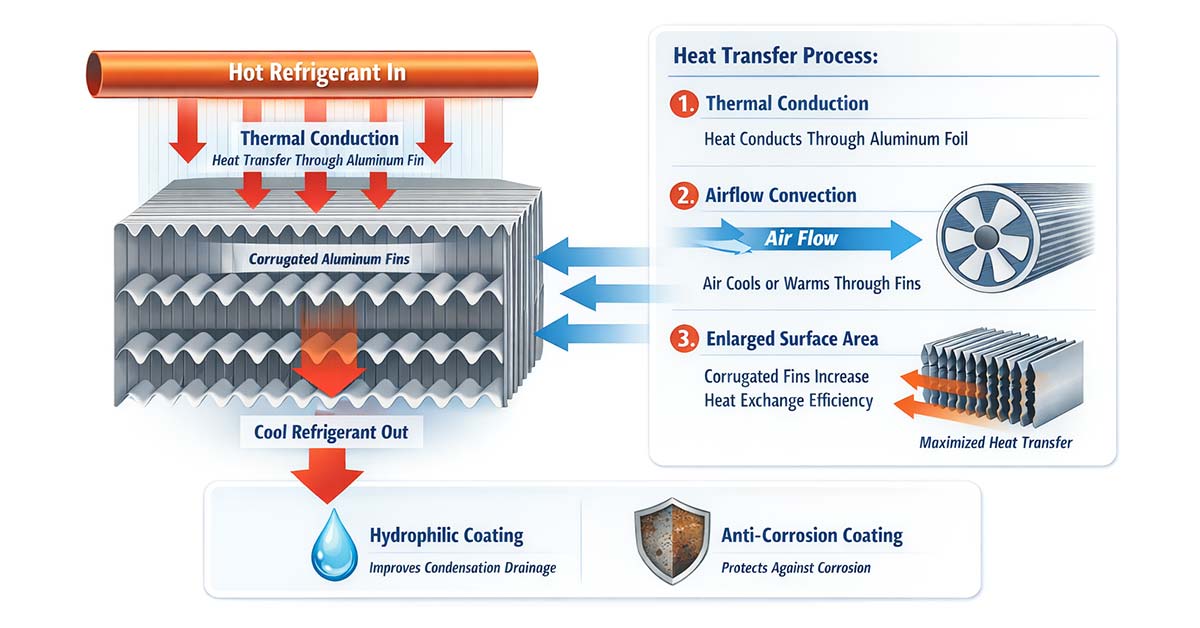

01. hermal Conduction

Aluminum has high thermal conductivity (≈ 200–235 W/m·K).

Heat moves rapidly through the thin aluminum fins from the heat source (refrigerant or hot fluid) to the outer surface.

Why thin foil matters:

- Thinner material = lower thermal resistance.

- Faster heat transmission.

- Higher system efficiency

02. Convection.

Air flows across the aluminum fins.

The fins transfer heat to (or absorb heat from) the moving air.

- In air conditioners → fins release heat (cooling mode condenser).

- In evaporators → fins absorb heat from indoor air.

The larger the air-contact area, the better the heat exchange.

03. Surface Area Amplification (Fin Structure)

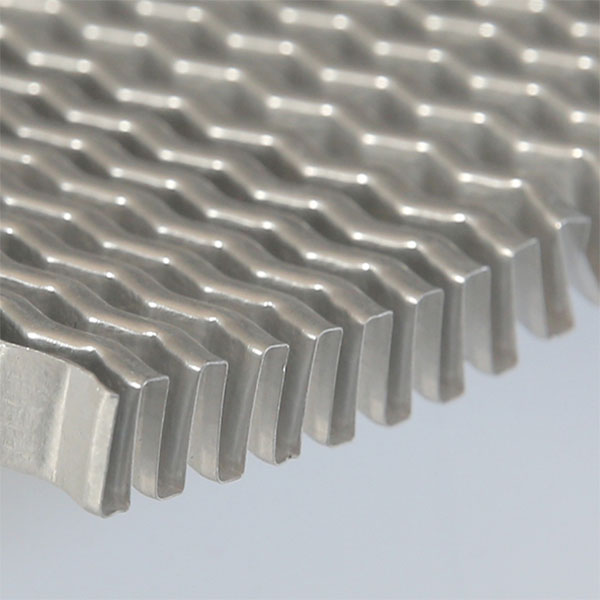

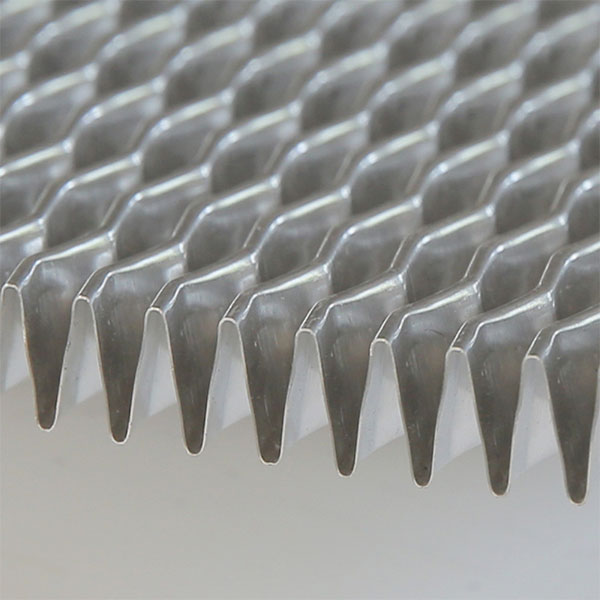

Finstock foil is stamped into corrugated or louvered fins.

Purpose:

- Increase surface area dramatically.

- Create turbulence in airflow.

- Improve heat exchange efficiency.

YUTWIN New Materials – Industrial Aluminum Foil Manufacturer

The aluminum foil is produced with strict thickness tolerance, superior flatness, and clean surface quality to meet demanding fin pressing requirements. It can be supplied in bare or coated conditions, depending on environmental and performance needs.

- High Thermal Conductivity

Enhances heat exchange efficiency and improves overall system performance.

- Excellent Formability

Optimized temper ensures smooth fin stamping without cracking or tearing.

- Uniform Thickness & Precision Control

Maintains consistent mechanical properties for high-speed automatic production lines.

- Good Corrosion Resistance

Suitable for humid, high-temperature, and corrosive environments.

- Coating Compatibility

Available with hydrophilic, anti-corrosion (blue/gold), or epoxy coatings.

Common Alloys & Tempers

| Alloy | Main Characteristics | Temper Options | Applications |

|---|---|---|---|

| 1100 | High purity, excellent conductivity | O / H14 / H24 | General HVAC fins |

| 1200 | Good formability and corrosion resistance | O / H14 / H24 | Residential air conditioners |

| 3003 | Higher strength with Mn addition | O / H14 / H24 | Commercial HVAC systems |

| 3102 | Enhanced corrosion resistance | O / H14 / H24 | Automotive heat exchangers |

Specifications

| Item | Specification |

|---|---|

| Thickness | 0.08 – 0.20 mm |

| Width | 100 – 1250 mm |

| Inner Core Diameter | 76 mm / 150 mm |

| Coil Weight | Customized |

Surface Treatment Options

- Bare Foil

Standard aluminum surface for general applications.

- Hydrophilic Coated Foil

Improves condensate drainage, prevents water droplet accumulation, and enhances heat exchange efficiency.

- Anti-Corrosion Coating (Blue/Gold)

Provides additional protection in coastal or industrial environments.

- Epoxy Coating

Offers superior long-term durability and resistance to chemical exposure.