5356 aluminum wire is a non-heat-treatable aluminum alloy from the Al–Mg series. It is well known for its excellent corrosion resistance, high strength, and good weldability. Compared with 5052 and 5056 alloys, 5356 provides higher strength and superior performance in welding applications, making it ideal for marine, automotive, and structural components exposed to harsh environments.

Description

Features

- Excellent Corrosion Resistance

Highly resistant to seawater, marine atmospheres, and industrial environments, making it suitable for outdoor and marine applications.

- Higher Strength than 5052 / 5056

Provides improved tensile and yield strength while maintaining good ductility.

- Superior Weldability

Widely used as filler wire for aluminum welding, offering excellent joint strength and minimal cracking.

- Good Formability and Ductility

Maintains good bending, drawing, and forming performance for fabrication and machining.

- Non-Heat-Treatable Alloy

Strength is achieved through strain hardening rather than heat treatment.

Specifications

| Item | Description |

|---|---|

| Alloy | 5356 |

| Aluminum Content / Chemical Composition | Al: Balance, Mg: 5.0–5.5%, Mn: 0.2–0.5%, Cr: 0.05–0.25%, Si: ≤ 0.25%, Fe: ≤ 0.4%, Cu: ≤ 0.1%, Zn: ≤ 0.25%, Ti: ≤ 0.2%, Others: ≤ 0.15% |

| Temper | O / H32 / H34 (customized) |

| Diameter Range | Customized according to requirements |

| Tensile Strength | According to temper |

| Elongation | According to temper |

| Surface Finish | Bright, mill finish, or anodizing grade |

| Straightness | According to standard or customized |

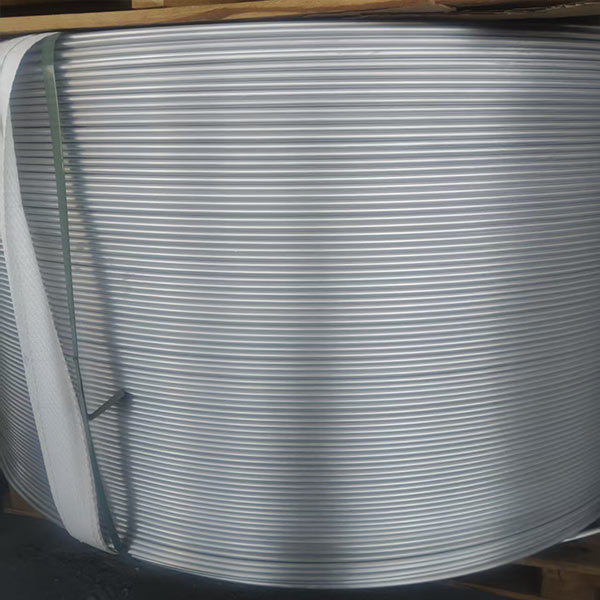

| Length | Coil, spool, or cut length |

| Packaging | Spool, coil, or drum |

| Standards | EN, ASTM, or customized |

Applications

- Marine and Offshore Components

Ideal for shipbuilding, marine fittings, and offshore structures due to excellent corrosion resistance.

- Welding Filler Wire

Widely used as filler material in aluminum welding, providing strong and durable joints.

- Automotive and Transportation Parts

Applied in brackets, structural components, and load-bearing parts exposed to corrosion.

- Industrial and Fabricated Components

Suitable for bent, drawn, or precision-formed aluminum wire components.

- Corrosion-Resistant Fasteners

Used for clips, connectors, and fasteners in outdoor or marine environments.

Packaging

| Packaging Type | Weight | Dimensions |

|---|---|---|

| Plastic Reel | 7 kg/reel | Outer Diameter: 270 mmBore Diameter: 52 mmHeight: 105 mm |

| Drum (Small) | 25–100 kg/drum | Outer Diameter: 460 mm Height: 280 mm |

| Drum (Medium) | 25–100 kg/drum | Outer Diameter: 570 mm Height: 380 mm |

| Drum (Large) | 25–100 kg/drum | Outer Diameter: 570 mm Height: 740 mm |

| Bundle | 10–40 kg/bundle | Outer Diameter: 570 mm Inner Diameter: 340 mm Height: 170 mm |