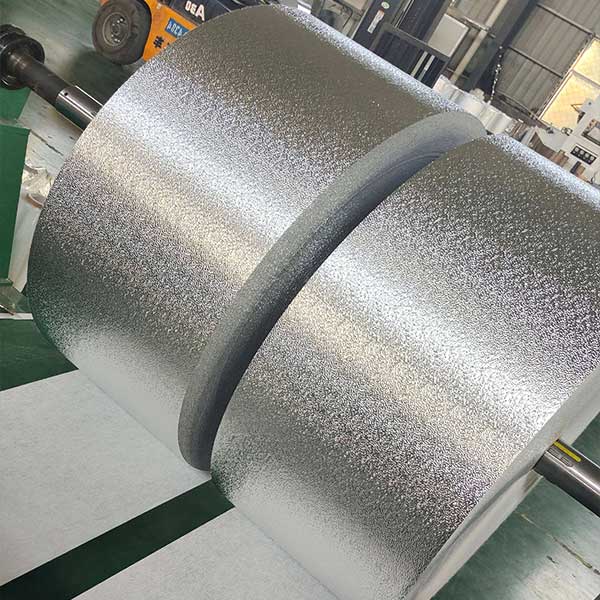

Embossed aluminum foil is an aluminum foil product processed with patterned rollers to form raised or recessed textures on the surface. The embossing process enhances the foil’s mechanical strength, rigidity, and decorative appearance while maintaining excellent barrier properties. It is widely used in packaging, insulation, and decorative applications.

Description

Features

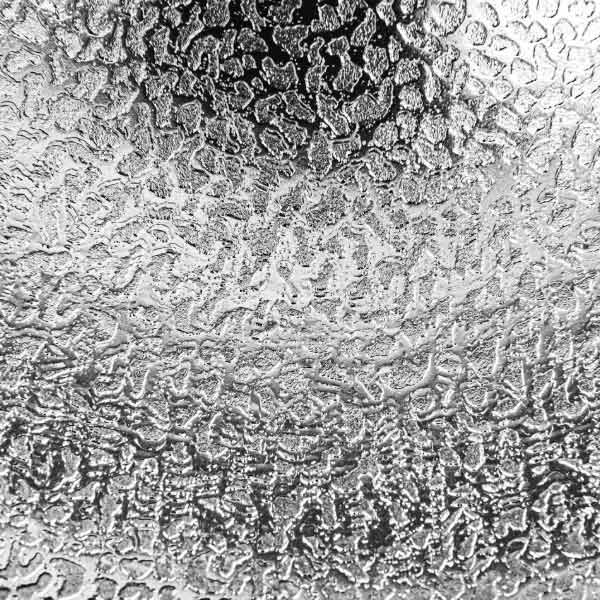

- Embossed Surface Design

Improves stiffness and tear resistance

- Enhanced Durability

Better puncture resistance compared with plain foil

- Excellent Barrier Properties

Effectively blocks moisture, oxygen, light, and odors

- Good Formability

Easy to shape, wrap, and laminate

- Decorative Appearance

Supports various patterns for functional and aesthetic purposes

- Corrosion Resistant & Lightweight

Inherits aluminum’s natural advantages

- Eco-Friendly

100% recyclable material

Specifications

| Item | Specification |

|---|---|

| Material / Alloy | 8011 / 1235 / 1145 / 1100 |

| Temper | O (Soft) |

| Thickness (mm) | 0.006 – 0.2 |

| Width (mm) | 100 – 1500 |

| Length | Customized (roll or sheet) |

| Surface Finish | Embossed (diamond, orange peel, custom patterns) |

| Standards | ASTM / EN / GB / Customized |

Applications

- Packaging Industry

Food packaging, pharmaceutical and cosmetic packaging.

- Thermal Insulation

HVAC insulation, building insulation, pipe wrapping.

- Industrial Use

Heat shielding, protective covers, lamination materials.

- Decorative Applications

Reflective panels, interior decoration, appliance surfaces.