Aluminum foil for packaging bags is specifically designed for flexible packaging bags. It is typically laminated with films such as PET, BOPP, NY, PE, and CPP, and is widely used in food, pharmaceutical, personal care, and industrial packaging, providing excellent sealing and protective properties.

Technical Specifications

| Item | Specification |

|---|---|

| Alloy | 8011 / 8079 / 1235 |

| Temper | O (Soft) |

| Thickness Range | 7 – 30 μm (commonly 9 / 12 / 15 / 18 / 20 μm) |

| Surface Treatment | Single-side or double-side coating / lamination treatment |

| Surface Condition | High cleanliness, low oil residue |

| Width | Customizable |

Description

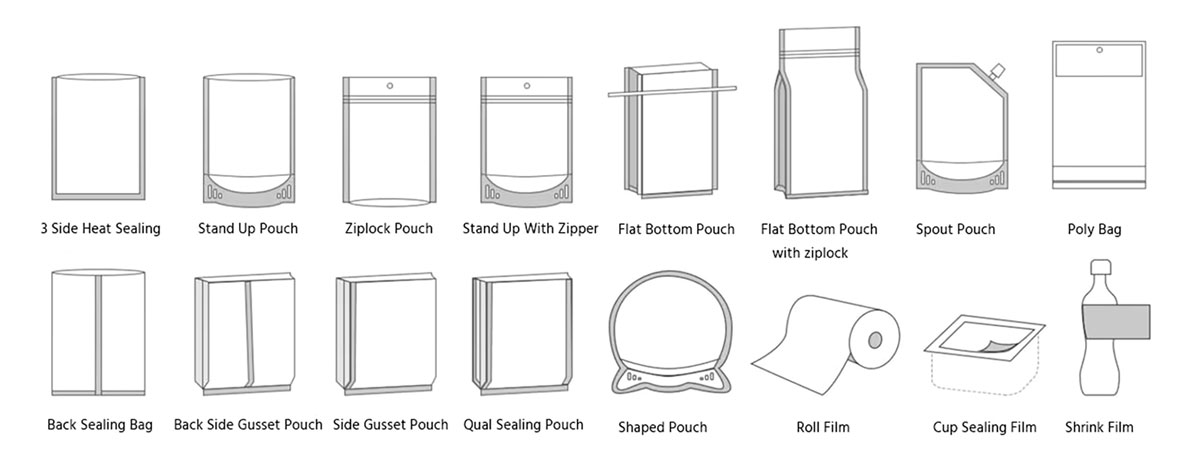

Aluminum Foil Bag Types

Features

- Excellent barrier properties against moisture, oxygen, light, and odors.

- Good sealing performance, compatible with various heat-seal layers.

- High mechanical strength, puncture and tear resistance.

- Excellent printability, suitable for high-quality multi-color printing.

- Food and pharmaceutical safety, compliant with contact material .regulations

Common Lamination Structures

PET / AL / PE

- Applications: Food packaging bags, seasoning bags, coffee bags.

- Features: High barrier, moisture and oxygen resistance, good heat-sealing performance.

BOPP / AL / PE

- Applications: Snack packaging, dry food packaging.

- Features: Good stiffness and excellent printability.

NY / AL / PE

- Applications: Vacuum bags, retort pouches.

- Features: High strength, puncture resistance, heat resistance.

Multi-layer Laminated Aluminum Foil Structures

- Applications: Liquid packaging bags, industrial packaging.

- Features: Customized barrier performance.