Aluminum Coils

Specifications

| Item | Specification |

|---|---|

| Thickness | 0.2 – 6.0 mm (Customizable: 0.1 – 12.0 mm) |

| Width | 100 – 2600 mm; Slit strip width: 10 – 600 mm |

| Alloy / Grade | 1000 Series: 1050, 1060, 1070, 1100, 1235, 1145, 1200, 1230, 1350. 2000 Series: 2024, 2A11, 2A12, 2A14, 2A17. 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, 3A22 5000 Series: 5005, 5052, 5056, 5083, 5086, 5182, 5454, 5754, 5059, 5A02, 5A03, 5A05, 5A06. 6000 Series: 6061, 6082, 6062, 6063, 6101, 6016, 6022, 6060, 6005. 7000 Series: 7005, 7A04, 7A09, 7050, 7075. 8000 Series: 8006, 8011, 8021, 8079. |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, T4, T5, T6 |

| Form | Coil / Sheet / Strip |

| Surface Finish | Mill Finish BrightFinish Embossed Brushed Anodized Painted |

| Protective Film | PE / PVC (Optional) |

| Inner Diameter | 508 mm / 610 mm |

| Standard | ASTM B209, EN 485, JIS, GB |

Yutewin New Materials

China’s Aluminum Material Expert

Yutewin New Materials specializes in the production of aluminum coils and sheets in a wide range of alloys, grades, and specifications, offering stable quality, flexible customization, and reliable supply to meet the diverse needs of different industries.

☑ Professional Manufacturer

Equipped with multiple hot-rolled and cold-rolled aluminum coil and sheet production lines, backed by extensive manufacturing experience and a stable supply capacity to meet the high-quality aluminum material demands of various industries.

☑ Diverse Product Range

A wide variety of product forms, including aluminum coils, sheets, and strips in multiple specifications, suitable for processing, secondary fabrication, and end-use manufacturing applications.

Customized Services

Personalized customization is supported, offering tailored solutions in dimensions, colors, and surface treatments to fully meet diverse and differentiated application requirements.

Product Form

Coil

Width: 600-2600mm

Strip

Width: 10-600mm

Sheet / Plate

Length: 2000-6000mm

Aluminum Grade

Based on different alloy compositions and properties, aluminum coils can be divided into several series, each differing in physical properties and application areas.

1000 Series

The 1000 series, also known as pure aluminum coils, has the highest aluminum content, over 99.00%. With minimal impurities, this series offers excellent corrosion resistance and thermal/electrical conductivity, though its mechanical strength is relatively low and cannot be enhanced by heat treatment.

3000 Series

Represented by 3003 and 3A21, the 3000 series is also called rust-resistant aluminum coil. Manganese (1.0–1.5%) is the main alloying element, improving strength while maintaining good corrosion resistance.

2000 Series

Represented by 2A16 and 2A12, the 2000 series is also called high-strength aluminum alloy. Copper (3.5–5.5%) is the main alloying element, providing excellent mechanical strength and hardness, making it suitable for aerospace, transportation, and structural applications.

5000 Series

The 5000 series is an aluminum-magnesium alloy, mainly alloyed with magnesium (3–5%). It has low density, high tensile strength, and good elongation, making it lighter than other series for the same area—ideal for weight-sensitive applications.

6000 Series

The 6000 series mainly contains magnesium and silicon, and is a cold-workable aluminum alloy. It offers good corrosion resistance and oxidation resistance, suitable for industrial and architectural applications requiring high durability.

7000 Series

The 7000 series is an aluminum-magnesium-zinc-copper alloy, classified as a heat-treatable, ultra-high-strength aluminum alloy. After processing, it exhibits high strength, wear resistance, low deformation, and minimal warping, making it essential for aerospace and high-end machinery.

8000 Series

The 8000 series aluminum coil mainly consists of aluminum-iron (Al-Fe) or aluminum-lithium (Al-Li) alloys, and is often used for packaging aluminum foil. This series is lightweight, corrosion-resistant, and highly workable, making it suitable for non-structural applications or areas requiring excellent corrosion and oxidation resistance.

Surface Treatment Processes for Aluminum Coil

Aluminum coil surface treatments are mainly used to improve corrosion resistance, decorative appearance, adhesion performance, and functional properties.

Polishing / Mirror

Mechanical or chemical polishing is used to make the aluminum surface smoother and brighter.

Brushed

Mechanical brushing creates uniform linear textures on the aluminum surface.

Anodizing

An electrochemical process that forms a dense oxide layer on the aluminum surface.

Coating / Painting

An organic or inorganic coating is applied to the aluminum surface, commonly PE, PVDF, or epoxy coatings.

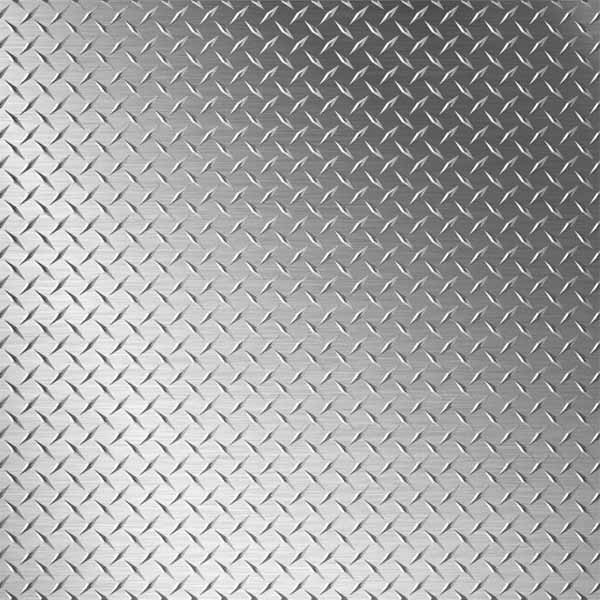

Embossed

Patterns are pressed onto the aluminum surface using embossing rollers.

Diamond

The surface features aluminum sheets embossed with a diamond pattern using a roller. This process creates a raised texture that enhances both functionality and aesthetics.

Application Industries of Aluminum Coil

Aluminum coils are widely used in building decoration, transportation, electronics, packaging materials and other fields, playing an important role in the national economy.

Construction and Decoration Industry

- Roofing panels and curtain wall panels

- Ceiling systems

- Door and window profiles

- Aluminum composite panel (ACP) substrates

Transportation Industry

- Automotive body panels and interior/exterior parts

- Truck bodies, refrigerated truck panels, box truck panels

- Rail transit interior and exterior panels

- Marine structural components

Packaging Industry

- Food aluminum foil

- Pharmaceutical blister packaging

- Beverage cans and easy-open cans

- Personal care and cosmetic packaging

Electronics and Electrical Industry

- Electrical appliance housings

- Heat sinks

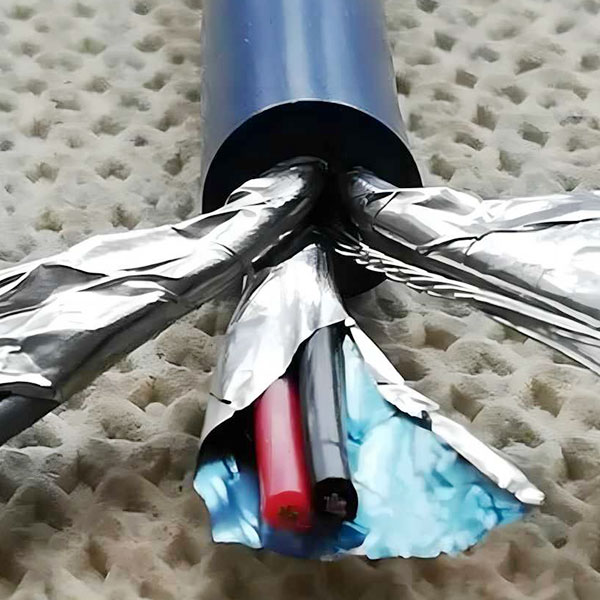

- Capacitor aluminum foil

- Cable shielding layers

Industrial Manufacturing

- Machinery and equipment enclosures

- Storage tanks and pressure vessels

- Piping and ventilation systems

- Industrial insulation and thermal protection

Energy and Power Industry

- Battery aluminum cases

- Photovoltaic mounting systems and reflective materials

- Electrical equipment covers

- Energy storage system components

Aerospace and High-End Equipment

- Aircraft skins and structural components

- Aerospace parts

- High-end equipment structural materials

Home Appliances and Consumer Goods

- Home appliance panels

- Furniture decorative panels

- Kitchen aluminum products

- Lighting fixtures and decorative parts