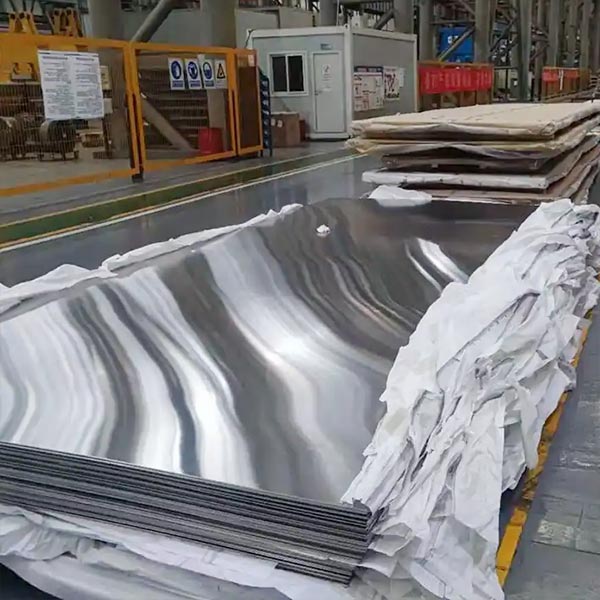

Aluminum sheet is a versatile, lightweight, and corrosion-resistant metal material for various architectural applications. It combines durability with aesthetic appeal, providing architects and builders with a material that is both functional and visually attractive. Its excellent weather resistance and easy formability make it ideal for exterior cladding, roofing, curtain walls, and decorative elements.

Specifications

| Item | Specification |

|---|---|

| Material / Alloy | 1100 / 3003 / 5052 / 6061 (customizable) |

| Temper | H14 / H18 / O / T4 / T6 (depending on alloy) |

| Thickness (mm) | 0.5 – 6.0 |

| Width (mm) | 1000 – 2000 (custom sizes available) |

| Length (mm) | 2000 – 6000 (custom lengths available) |

| Surface Finish | Mill finish, Brushed, Anodized, PVDF coated, Color-coated |

| Standards | ASTM / EN / GB / JIS / Customized |

| Fire & Weather Resistance | Excellent corrosion resistance, UV resistance, and fireproof options |

Description

Applications

- Exterior Cladding

Facades, curtain walls, decorative panels.

- Roofing & Ceiling

Lightweight roofing sheets, interior ceiling panels.

- Architectural Elements

Sunshades, canopies, louvers, decorative trims.

- Doors & Windows

Aluminum sheets for frames, panels, and protective surfaces.

- Signage & Interior Decoration

Aluminum panels for commercial and residential buildings.

Features of aluminum sheets

- Lightweight & Strong

Reduces structural load while providing excellent mechanical strength.

- Corrosion Resistant

Withstands harsh weather and environmental conditions.

- Durable & Long-Lasting

Maintains appearance and performance over years.

- Easy to Fabricate

Can be cut, bent, drilled, or stamped according to design requirements.

- High Reflectivity & Aesthetic Finish

Available in plain, brushed, anodized, or painted surfaces.

Core Development Trends in Architectural Aluminum Panels

- Lightweighat and Composite Materials

Aluminum honeycomb panels, aluminum-plastic composite panels, and aluminum core foam panels are becoming mainstream, balancing lightweight properties with structural strength and reducing building load.

- Green and Environmentally Friendly

Using recyclable aluminum panels and surface treatments with water-based and solvent-free paints, aligning with building carbon neutrality and green building standards.

- Integrated Functionality

Aluminum panels integrate functions such as heat insulation, thermal insulation, sound insulation, and photovoltaic power generation (photovoltaic aluminum panels), achieving a dual value of “decoration + function.”

- Customized and Artistic Design

Supporting irregular shape processing and personalized surface treatments (imitation stone, imitation wood, gradient colors) to meet the artistic design needs of modern architecture.