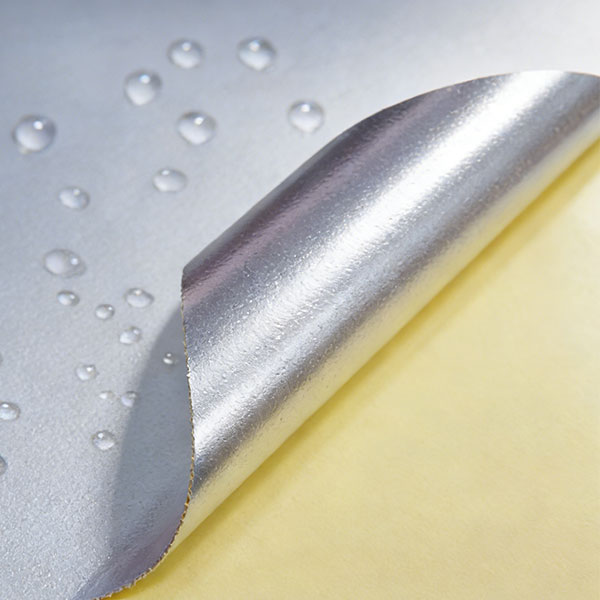

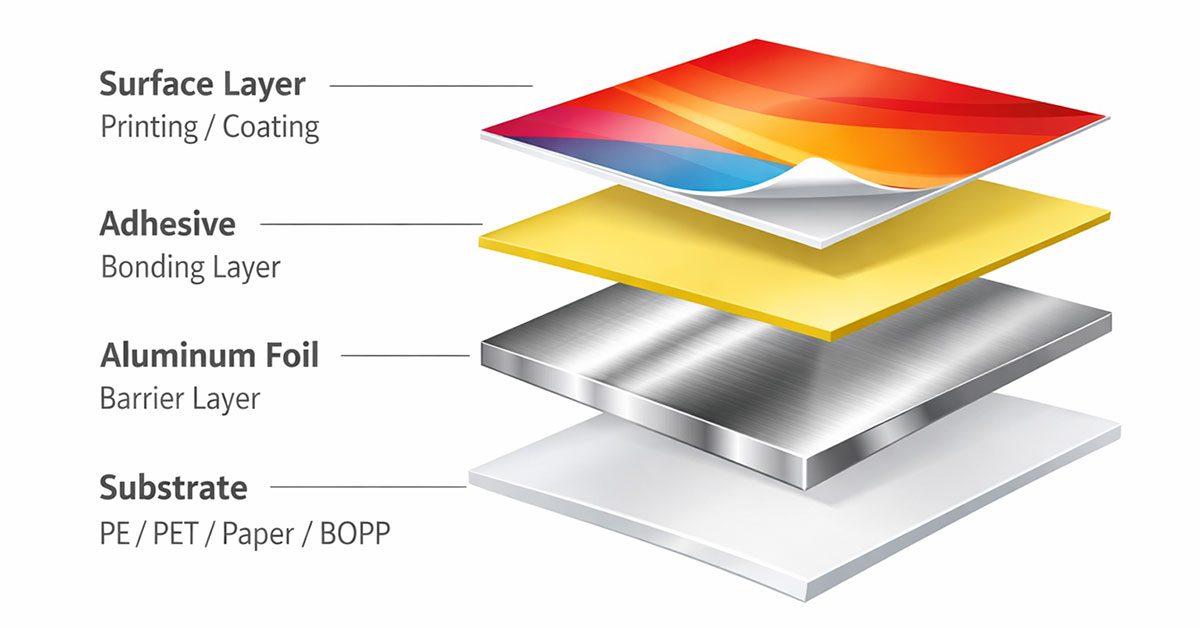

Laminated aluminum foil is a composite material produced by bonding aluminum foil with other substrates such as paper, PE, PET, BOPP, or non-woven fabrics. Through lamination, the material combines the excellent barrier properties of aluminum foil with the strength, flexibility, or printability of other materials, making it ideal for high-performance packaging and insulation applications.

Description

Features

- Excellent Barrier Performance

Provides superior protection against moisture, oxygen, light, and odors

- Enhanced Mechanical Strength

Improved tear resistance and durability after lamination

- Good Heat Sealability

Compatible with heat sealing and various packaging processes

- Excellent Printability

Suitable for high-quality printing and branding

- Good Flexibility & Formability

Easy to convert, fold, and shape

- Wide Material Compatibility

Can be laminated with paper, plastic films, or fabrics

- Eco-Friendly Options Available

Recyclable or mono-material solutions upon request

Specifications

| Item | Specification |

|---|---|

| Material / Alloy | 8011 / 1235 / 1145 / 1100 |

| Temper | O (Soft) |

| Foil Thickness (mm) | 0.006 – 0.05 |

| Lamination Material | Paper / PE / PET / BOPP / Non-woven (customizable) |

| Total Thickness | Customized |

| Width (mm) | 100 – 1500 |

| Length | Customized (roll or sheet) |

| Surface Finish | Plain / Printed / Coated |

| Processing Type | Laminated aluminum foil |

| Standards | ASTM / EN / GB / Customized |

Applications

- Flexible Packaging

Food, pharmaceutical, and cosmetic packaging.

- Insulation Materials

Thermal insulation for HVAC, buildings, and pipelines.

- Industrial Packaging

Protective packaging for chemicals and sensitive products.

- Household & Commercial Use

Packaging, wrapping, and insulation applications.