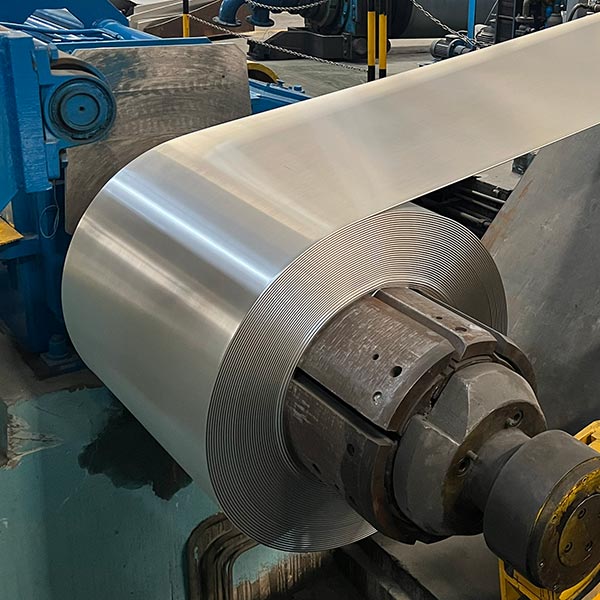

3003 aluminum coil belongs to the 3000 series aluminum alloy, with manganese (Mn) content ≈ 1.0% and aluminum content ≥ 96.8%. This alloy is known for its excellent corrosion resistance, good formability, and higher strength compared to 1000 series aluminum, along with good thermal conductivity and weldability. 3003 Aluminum Coil is widely used in construction, transportation, industrial manufacturing, and kitchenware.

Specifications

| Parameter | Description |

|---|---|

| Alloy | 3003 |

| Chemical Composition (%) | Al ≥ 96.8, Mn 1.0 – 1.5, Cu ≤ 0.10, Fe ≤ 0.7, Si ≤ 0.6, Zn ≤ 0.10, Ti ≤ 0.15, Others ≤ 0.15 |

| Temper | H14, H18, H24, O (Soft) |

| Thickness Range | 0.2 – 6.0 mm (customizable) |

| Width | Customizable (20 – 2000 mm) |

| Coil Weight | Customizable |

| Inner Diameter (ID) | 150 / 300 / 505 mm |

| Surface Finish | Mill Finish, Bright, Brushed, Coated, Film Laminated (optional) |

| Standard | ASTM B209 / EN AW-3003 / GB/T 3880 |

Description

Features

- Aluminum–manganese alloy (Al–Mn)

Belongs to the 3xxx-series aluminum alloys, with manganese as the main alloying element, offering improved strength over pure aluminum.

- Medium mechanical strength

Stronger than 1000-series aluminum, suitable for general structural and load-bearing applications.

- Excellent corrosion resistance

Provides reliable resistance to atmospheric, marine, and industrial environments.

- Good formability and workability

Soft and ductile, easy to roll, bend, stamp, and deep-draw, suitable for thin-gauge processing.

- Good thermal and electrical conductivity

Suitable for heat dissipation and low-load electrical applications.

- Smooth and uniform surface finish

Ideal for anodizing, painting, coating, embossing, or film lamination.

- Good weldability

Compatible with TIG, MIG, and spot welding, enabling reliable fabrication.

- Lightweight material

Low density supports weight reduction in structural and decorative applications.

Applications

- Construction & Decoration

Roofing, curtain walls, ceilings, decorative panels.

- Transportation

Shipbuilding, automobile body panels, trailer panels.

- Industrial Manufacturing

Stamped parts, sheet metal components, equipment enclosures.

- Kitchenware

Cookware, food containers.

- Heat Dissipation & Conductivity

Heat exchangers, heat sinks.