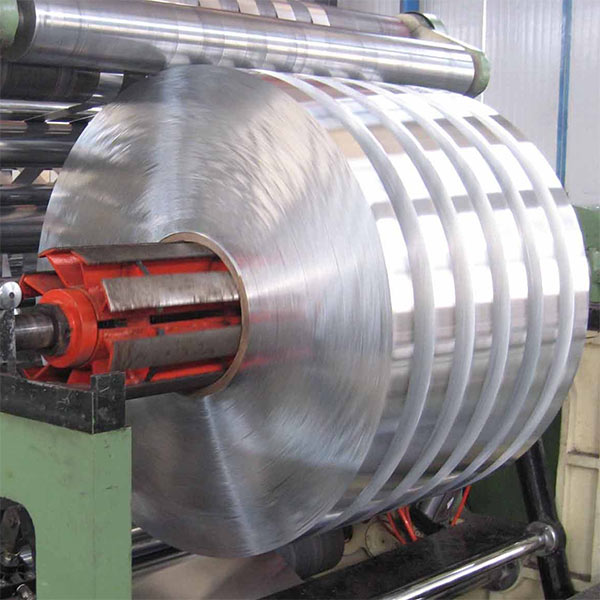

Cable foil is used to manufacture cables for a variety of applications, including power cables and communication cables. It is commonly used in high-performance cables such as telecommunications, data transmission, and distribution cables. Aluminum foil helps reduce noise and crosstalk between conductors within the same cable, thus maintaining signal integrity. Compared to other metals, aluminum foil is an inexpensive material, making it an economical choice for manufacturers.

Technical Specifications

| Item | Specification |

|---|---|

| Alloy | 8011 / 1235 |

| Temper | O (Soft) |

| Thickness Range | 6 – 50 μm (commonly 9 / 12 / 15 / 20 μm) |

| Width | Customizable |

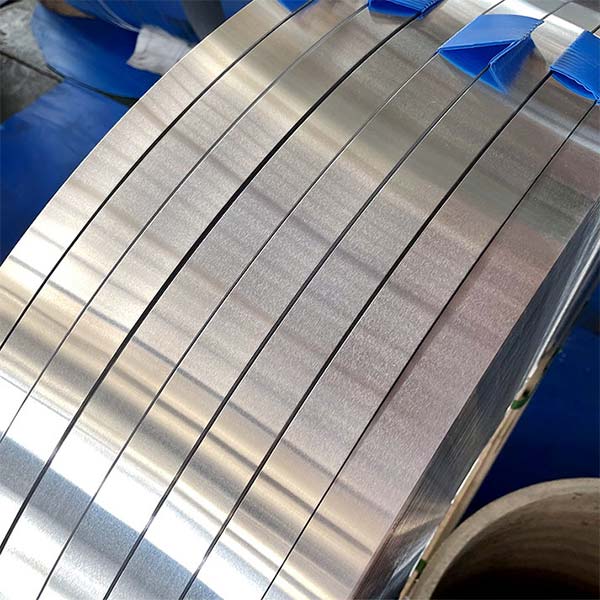

| Surface Treatment | Bright / Coated for corrosion resistance |

| Special Features | Heat-resistant, fire-resistant, corrosion-resistant |

Description

Features

- Excellent shielding performance against electromagnetic interference (EMI).

- High conductivity and flexibility, suitable for current transmission and winding.

- Corrosion-resistant and moisture-proof, extending cable service life.

- Good mechanical properties, puncture and tear-resistant.

- Compatible with various insulation materials, enhancing overall cable performance.

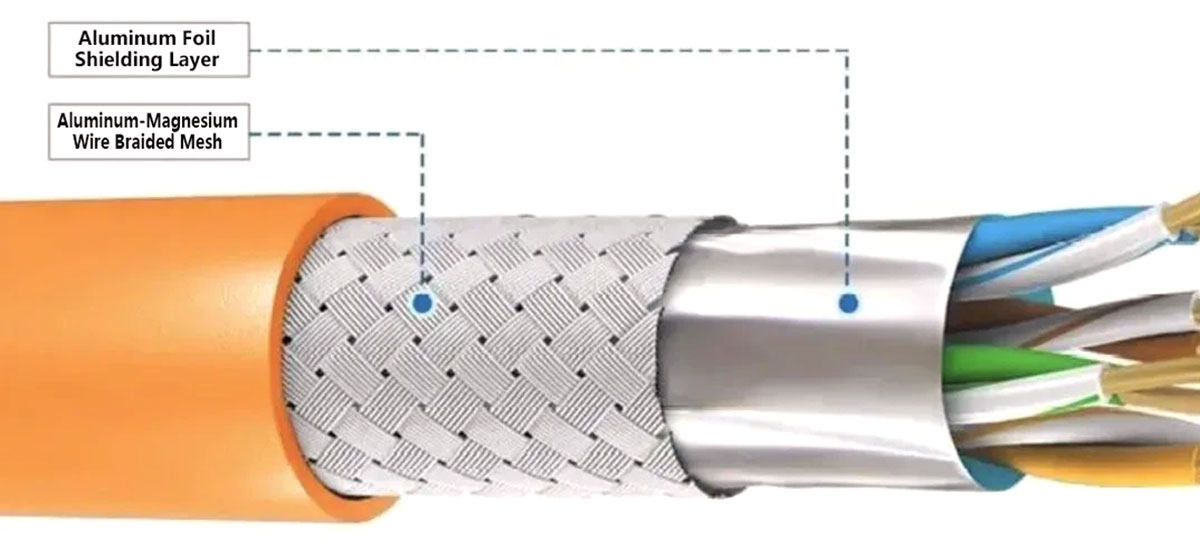

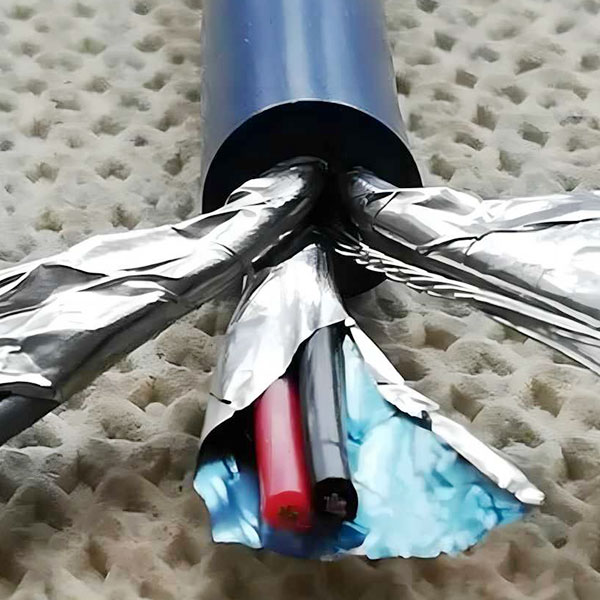

Structure

In cables, aluminum foil can be wrapped around the inner conductor or braided into a braided structure. It can also be used as part of a multi-layered structure, often in combination with other materials such as plastic insulation, metal braids, and other conductive layers.