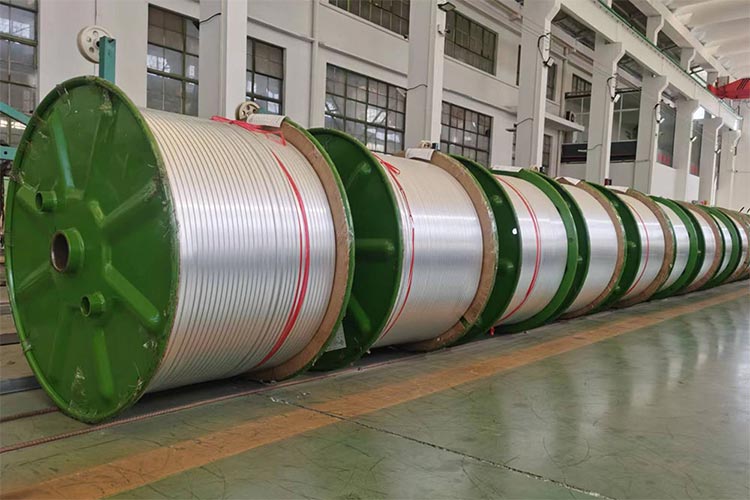

Aluminum Wires

YUTWIN New Materials specializes in the advanced processing of aluminum and aluminum alloy materials, offering stable production of high-quality aluminum wire in a wide range of alloys and specifications. Manufactured from premium aluminum ingots through continuous wire drawing, precise heat treatment, and comprehensive quality inspection, our products deliver excellent dimensional consistency, mechanical performance, and surface quality. They are widely used in electrical, mechanical, construction, and various industrial manufacturing applications.

Specifications

| Item | Specification |

|---|---|

| Diameter Range | 0.2 mm – 20.0 mm (Customizable) |

| Diameter Tolerance | ±0.01 mm to ±0.05 mm (depending on size) |

| Form | Coil / Straight Cut |

| Cut Length | Cut to customer requirements |

| Alloy Grades | 1xxx Series (Pure Aluminum): 1100, 1060. 2xxx Series (Al-Cu): 2011, 2014, 2017, 2024. 3xxx Series (Al-Mn): 3003. 4xxx Series (Al-Si): 4032. 5xxx Series (Al-Mg): 5005, 5052, 5154, 5056, 5083. 6xxx Series (Al-Mg-Si): 6011, 6060, 6061, 6063, 6082, 6106, 6201, 6262, 6351. 7xxx Series (Al-Zn-Mg): 7001, 7003, 7005, 7050, 7075. |

| Supply Temper | O, H12, H14, H18, T4, T5, T6 |

| Surface Finish | Mill finish / Polished / Pickled (customized) |

| Standards | GB / ASTM / EN |

| Packaging | Wooden spool / Plastic spool / Moisture-proof packaging |

Features of Aluminum Wire by Alloy Series

1xxx Series (Pure Aluminum: 1100, 1060)

- Excellent electrical and thermal conductivity

- Superior corrosion resistance

- Easy to form, bend, and draw

- Commonly used in power conductors, architectural decoration, and light industrial components

2xxx Series (Al-Cu: 2011, 2014, 2017, 2024)

- High-strength aluminum wire

- Good machinability

- Suitable for high-strength structural parts and precision mechanical components

- Commonly used in aerospace and automotive precision parts

3xxx Series (Al-Mn: 3003)

- Excellent corrosion resistance and good formability

- Moderate strength

- Suitable for architectural curtain walls, roofing, lightweight structural components, and decorative materials

4xxx Series (Al-Si: 4032)

- High wear resistance and rigidity

- Low thermal expansion coefficient

- Commonly used in automotive engines and friction parts

5xxx Series (Al-Mg: 5005, 5052, 5154, 5056, 5083)

- Excellent corrosion resistance, especially in marine environments

- Medium to high strength, easy to process

- Widely used in shipbuilding, automotive components, industrial containers, and construction structures

6xxx Series (Al-Mg-Si: 6011, 6060, 6061, 6063, 6082, 6106, 6201, 6262, 6351)

- Well-balanced mechanical properties

- Easy to process, extrude, and draw

- Suitable for architectural profiles, automotive parts, structural components, and industrial machinery parts

7xxx Series (Al-Zn-Mg: 7001, 7003, 7005, 7050, 7075)

- High-strength aluminum wire for heavy-load applications

- Excellent response to heat treatment strengthening

- Commonly used in aerospace, automotive structural parts, and high-strength mechanical components

Main Applications of Aluminum Wire

Electrical & Electronics Industry

- Power conductors

- Cable shielding wires

- Electrical connectors

- Transformer and winding materials

Mechanical Processing & Fasteners

- Screws, rivets, and pins

- Turned parts and aluminum wire for automatic lathes (e.g., 2011, 6262)

Construction & Decoration

- Aluminum woven mesh

- Curtain walls and decorative components

- Ceilings and lightweight structural elements

Industrial & Transportation Applications

- Automotive components

- Aerospace structural parts

- Marine and offshore engineering components

Welding & Forming Applications

- Welding wire raw material

- Aluminum wire for weaving, stretching, and cold heading