Aluminum sheets for shipbuilding are specially developed for marine environments, offering an excellent combination of high strength, corrosion resistance, and lightweight performance. Compared with traditional steel, marine-grade aluminum significantly reduces vessel weight, improving fuel efficiency, payload capacity, and overall sailing performance.

Description

Specifications

| Item | Specification |

|---|---|

| Alloy | 5083 / 5086 / 5052 / 5456 / 6061 |

| Series | 5000 Series (Al-Mg) / 6000 Series |

| Temper | O / H111 / H112 / H116 / H321 |

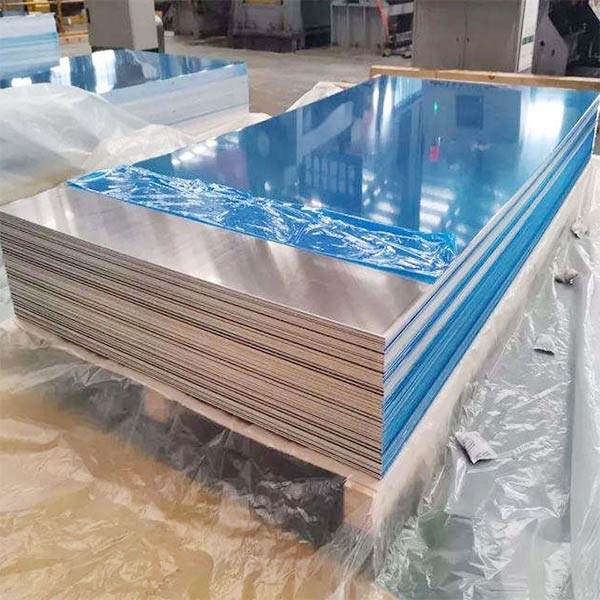

| Thickness | 0.8 – 50 mm |

| Width | 1000 – 2500 mm |

| Length | 2000 – 12000 mm |

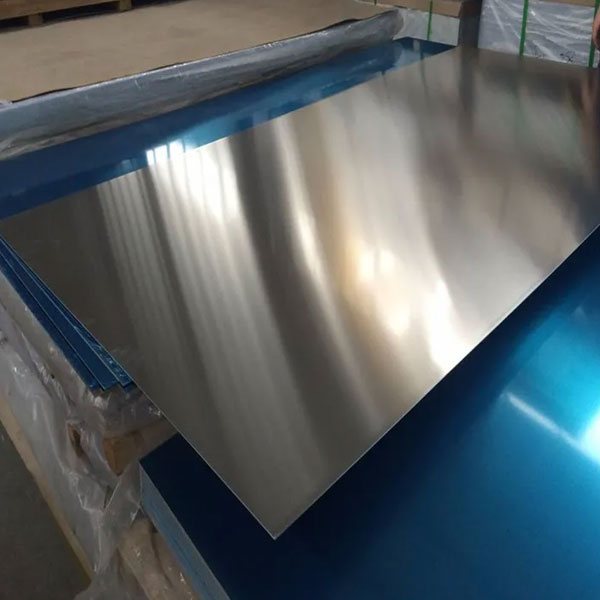

| Surface Finish | Mill Finish / Protective Film |

| Standards | ASTM B928 / ASTM B209 / EN 485 / EN 573 / JIS H4000 |

| Classification Approval | CCS / DNV / ABS / BV (optional) |

| Processing | Cutting, CNC Machining, Welding Preparation |

Why Aluminum Sheet for Shipbuilding?

- Lightweight Design

Reduces vessel weight by 30–40% compared with steel, improving speed and fuel efficiency.

- Excellent Corrosion Resistance

Aluminum-magnesium alloys perform exceptionally well in seawater and marine atmospheres.

- Good Weldability & Fabrication

Suitable for complex ship structures and modular construction.

- Low Maintenance & Long Service Life

No rusting, reduced coating requirements, and lower lifecycle costs.

- Environmentally Friendly

100% recyclable and aligned with modern green shipbuilding standards.

Main Alloy Grades and Applications

- 5083 Aluminum Sheet

It is an Al-Mg series alloy with high magnesium content, which has medium strength, excellent corrosion resistance and welding crack resistance. It is widely used in key parts of ships such as ship decks, engine bases, ship sides, and bottom outer plates, and is suitable for various ships such as fishing boats, cargo ships, and yachts.

- 5052 Aluminum Sheet

Also an Al-Mg series alloy, it has good corrosion resistance, weldability, and cold processing performance, with medium strength. It is often used in small ships such as yachts, fishing boats, and sightseeing boats, as well as components such as portholes and gangways.

- 5086 Aluminum Sheet

An Al-Mg series alloy with excellent electrical conductivity and extremely strong corrosion resistance. It is mainly used in ship fuel systems, seawater storage tanks, and pressure vessels and other parts, and its corrosion resistance is better than that of 5052, suitable for high-corrosion environments.

- 5454 and 5456 Aluminum Sheets

5454 is the preferred material for marine applications, and 5456 has higher strength, both with excellent corrosion resistance. They are used in seawater storage tanks, pressure vessels, structural components, and other parts, suitable for heavy ships.

- 6061 Aluminum Sheet

It is an Al-Mg-Si series alloy, a precipitation-hardening type, with good weldability and mechanical properties. It is mainly used in ship accessories, hardware, instrument brackets, and other parts, and is suitable for precision parts due to its good processing performance.