In the electronics industry, aluminum sheet is far more than a simple “casing material.” As devices evolve toward being thinner, lighter, and more highly integrated, aluminum alloys have become indispensable. They serve as critical physical carriers due to their excellent thermal conductivity, electromagnetic shielding capabilities, and premium finish.

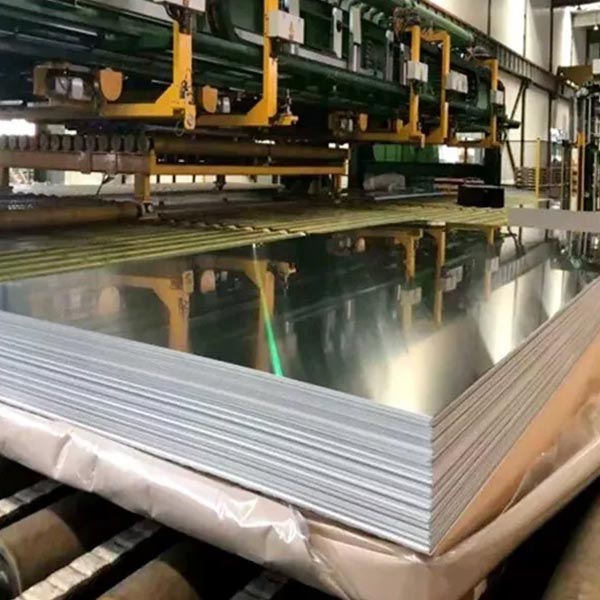

Description

Why does the electronics industry favor aluminum so heavily?

- Thermal Management

With a thermal conductivity of approximately 237 W/(m·K), aluminum is significantly more efficient than stainless steel. It rapidly dissipates heat generated by high-performance processors.

- EMI Shielding

Aluminum sheets effectively block Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI), protecting precision components from external signals and preventing the device from emitting excessive radiation.

- Aesthetics & Finish

Aluminum has excellent anodizing properties. It can be dyed in various colors and finished with textures like sandblasting, brushing, or high-gloss polishing.

- High Specific Strength

Aluminum maximizes structural integrity while minimizing device weight, which is crucial for the portability of laptops and handheld devices.

Common Alloy Grades & Applications

Demand in the electronics sector is generally divided into “Cosmetic Parts” and “Structural/Thermal Components”:

| Alloy Series | Representative Grades | Characteristics | Typical Applications |

| 1xxx Series | 1050, 1060 | High purity (>99%), best electrical/thermal conductivity, very soft. | Capacitor foils, transformer strips, heat sink fins. |

| 3xxx Series | 3003 | Manganese-added for better rust resistance and excellent stamping. | Battery casings (e.g., power battery shells), stamped electronic parts. |

| 5xxx Series | 5052, 5754 | Medium strength, superb workability, stable anodizing results. | Most common. Laptop casings, tablet backplates, TV frames. |

| 6xxx Series | 6061, 6063 | Heat-treatable for high hardness; ideal for precision CNC machining. | Smartphone mid-frames, precision instrument panels, high-end audio chassis. |

Surface Treatment

- Anodizing

Creates a hard, corrosion-resistant, and colorable oxide layer.

- Laser Etching

Used for logos, button markings, or anti-counterfeiting codes.

- Conductive Oxidation

Provides corrosion resistance while maintaining electrical conductivity for grounding purposes.