Description

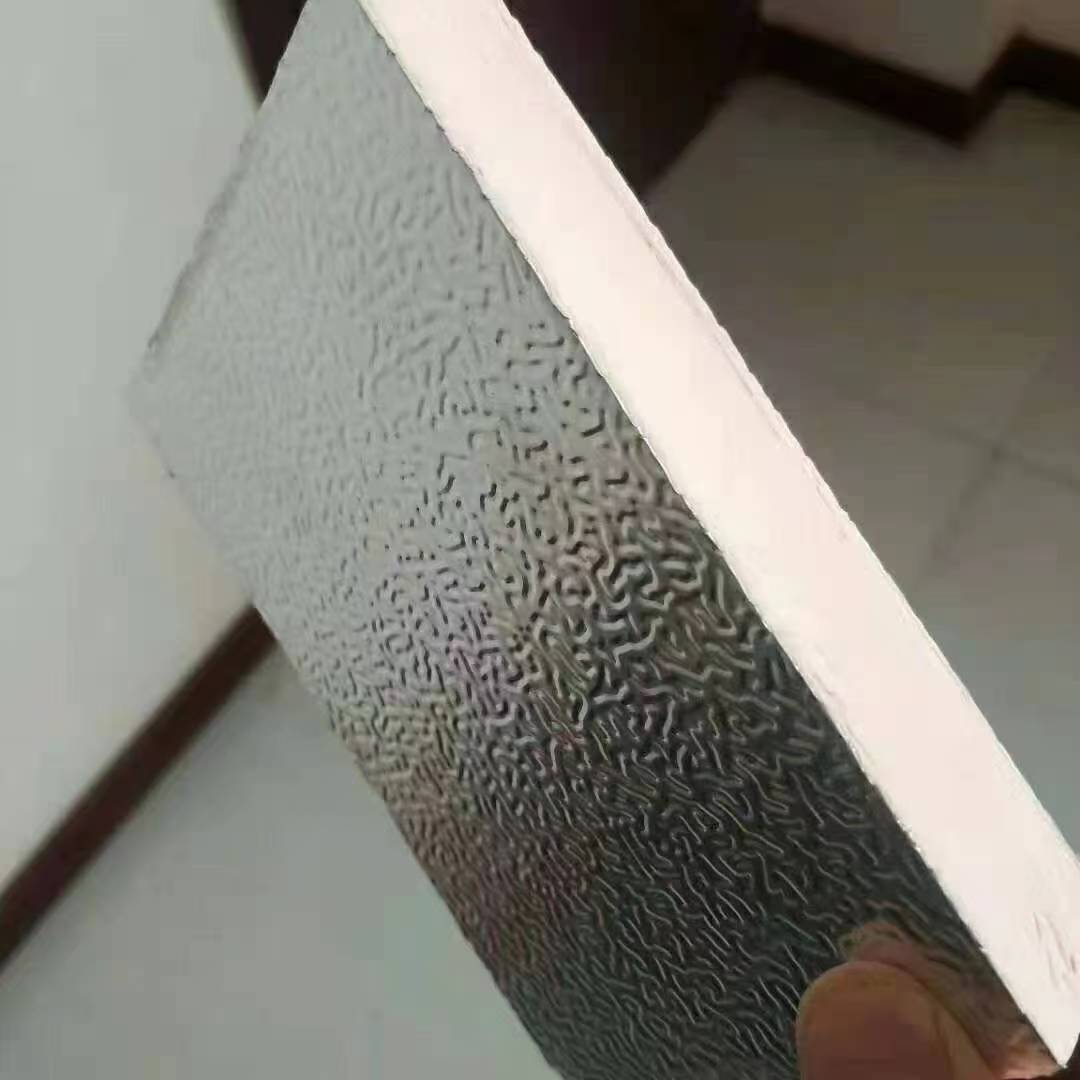

High-Performance Aluminum Foil for Central Air Conditioning Systems

Optimize HVAC Efficiency with Premium-Grade Aluminum Foil

Our specially engineered aluminum foil is designed to meet the rigorous demands of modern central air conditioning systems. From duct insulation to seam sealing, it ensures superior thermal performance, corrosion resistance, and long-term reliability.

Common Applications

-

Duct Lining & Wrapping

-

Insulate supply and return air ducts to prevent condensation and heat gain/loss.

-

Form a seamless thermal barrier that conforms to curves and corners.

-

-

Casing & Plenum Insulation

-

Line metal cabinet interiors to maintain airflow temperature.

-

Improve occupant comfort by reducing “cold spots” in conditioned spaces.

-

-

Seam & Joint Sealing

-

Seal duct joints, sheet-metal seams, and access panel overlaps.

-

Prevent air leakage and maintain system pressure balance.

-

-

Equipment Covers & Guards

-

Wrap coils and piping to protect against environmental contaminants.

-

Shield control boxes and vulnerable components from heat and moisture.

-

Technical Specifications

| Property | Specification |

|---|---|

| Base Material | 100% pure aluminum |

| Standard Thickness | 0.05 mm (50 μm) |

| Peel Strength (with PSA) | ≥ 1.5 N/cm |

| Temperature Range | – 40 °C to 150 °C |

| Reflectivity | ≥ 95% |

| Backing Options | Fiberglass, Non-woven PET (Class A fire-rated) |

| Roll Widths | 150 mm, 300 mm, 600 mm |

| Roll Lengths | 25 m, 50 m |

Frequently Asked Questions

Q: Can this aluminum foil handle outdoor ductwork?

A: Yes, the corrosion-resistant surface and optional weatherproof backing make it suitable for exposed outdoor installations.

Q: Is the PSA-backed version compliant with building codes?

A: Our PSA-backed foil meets UL 723 (ASTM E84) Class A requirements and is approved for use in commercial and residential HVAC systems.

Q: How do I repair a tear in the foil?

A: Clean around the damaged area, then patch with a small piece of the same foil using overlap and sealing with mastic or PSA.