Introduction

Aluminum coil is a very flexible form of materials that is widely applied in the fields of manufacturing and construction. It is manufactured in continuous rolls providing uniform thickness, width and strength in long rolls. Aluminum coil is sold at aluminum metal.com to use as exterior panels roofing, curtain walls, HVAC systems and as general fabrication. It has the advantages of high strength to the weight ratio corrosion resistance formability and sustainability.

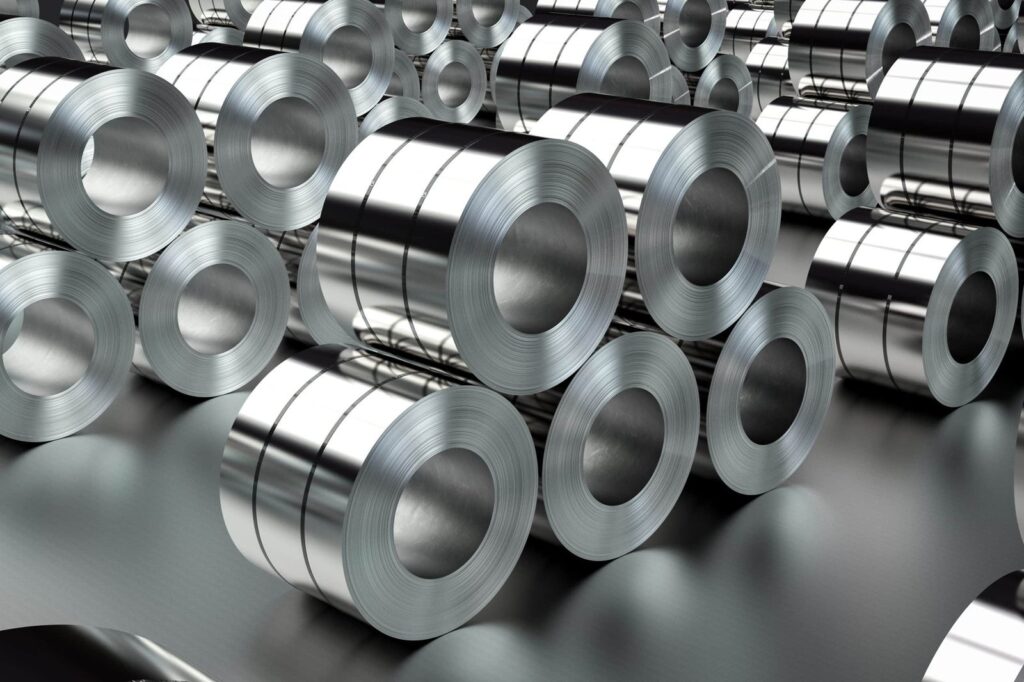

What is Aluminum Coil?

The Aluminum coil is a strip of aluminum rolled into a long strip and wound into continuity. It can be subjected to surface treatment such as, painting at coating to increase durability, appearance and protection against corrosion. Such coils are able to be processed through cutting bending stamping or forming to produce elements of various industries.

This is because stamping press feeding and roll forming establish effective production processes, which makes continuous roll a favorable production format in factories and construction projects.

Advantages of the Aluminum Coil

Outstanding Resistance to weight ratio

The Aluminum coil is very strong yet very light. This makes it suitable in structural applications like roofing siding and the curtain wall where there is need of bearing the load and be stable without providing too much load.

Corrosion Resistance

Natural resistance to corrosion is one of the most useful aspect of aluminum coil. The protective oxide layer on the metal contains chemicals on the protection of moisture and environmental stress. Anodized or coated forms have increased life in severe outside surroundings.

Blast Resistance and Weather Resistance

Aluminum coil is difficult to body UV exposure rain wind and temperature change. They retain the aspect and structurally stable throughout many decades, which is why they are trusted to be used in roofing siding and facades.

Facility of Fabrication and Forming

The flexibility in fabrication of aluminum coil makes it adaptable in stamping roll forming, press forming and bending. Cut fabricate or shape is so easy to die and fit to use in roofing profiles, window frames and the like.

Flexibility in during Treatment of Surfaces

Aluminum coil can be either mill-finished or painted to various colors either by anodized painting_{polyester} coating or PVDF systems depending on the color finish and protection. These alternatives favor architecture aesthetics and durability.

Heat and Electric Resistance

Aluminum coil has a good thermal conductivity that finds application in heat exchanger fin in air conditioning ducts and electrical enclosures where dissipation of heat is significant.

Recycling and Sustainability

Coil like the other aluminum formats is completely recyclable. The post-consumer or post-industrial scrap may be reclaimed using small amount of energy. Aluminum coil promotes the circular economy trends and the sustainable building certification.

Industrial and Architectural Applications

Roofing and cladding

Roof sheets gutters downspouts soffits and eaves products are common in the use of the aluminum coil. It is used as a favorite roofing material due to its weather and longevity. Applications of cladding are decorative and decors, curtain walls exterior envelope panels, and decorative facades.

Curtain Walls Building Envelope

Curtain wall systems siding and exterior panels are made of aluminum coil used by the architects. Space capabilities include supporting large spans and continuity across the facades, and the product is lightweight and rigid, as well as finish-customizable.

Ducting and HVAC equipment

The coated coils are formed into heat exchanger fins air conditioning ducts and housing of HVAC. The resistance to corrosion in the thermal conductivity and the accurate thickness enhance air control and heat exchange due to their superiority.

Automobiles and Transport

Liability Aluminum coil is strong and is light. It is a light addition of strength to lighter moving trailers and train car siding, and cargo partitions in vehicles. It also is used in decorative trim and trim used on the inside panels because of its flexibility and surface finish.

Industrial Equipment/ Machinery

Aluminum coil can be used as machineries panel enclosure, enclosure system on the conveyor and guard covers. The ready formability and the corrosion resistance promote life of operation in a variety of conditions.

Decorative and Signage

Aluminum coil is fabricated into sheet signage, decorative panel kiosks, shells and advertisement boards. The hard surface accepts paint and graphic material easily and is used in store design and visual merchandizing.

Options on Customizations of Materials

The Aluminum metal.com sells alloyed and tempered coils based on mechanical specifications. The thickness and length of the coil widths are associated with customization in size. The surface finishing is available as mill finish, anodizing, coil coated, painted. This form of flexibility makes such coils adapt to the project needs.

Distinctions of Alloy and Temper

Various alloy series with tempers provide strength ductility and corrosion resistance to use in sheets, cladding or in structure fabrication.

Width and Thickness Promoting

The thickness of the coil can vary to decorative levels of thin plating (gauges) to thicker structural panels. Thickness is at par with coil handling equipment and material.

Finishing and Paint Color

Coatings can be chosen as polyester paint anodized finishing or PVDF topcoats of different colors and textures. These films make finishing and adorning aluminum structures.

Fabrication Techniques

Roll Forming

Profiles such as roofing panels, gutter segments and framing members are made by continuous coil feed into roll forming machineries.

Bending using Press Brake

Pieces cut coil are bent to forms windows frames, trims, connecter or bracket or flashing.

Stamping and Punching

Areas that produce high volume parts such as trimming of the HVAC fins or bracket pieces are stamped to specification through the use of dies to utilize the coil.

Reducing and splitting

Coil splitting in to smaller strips or cutting to specific lengths provides ready to process or install material.

Performance Advantages

And longevity and low maintenance

Rust fading cracking and warping does not take place in coated aluminum coil. This will help cut down on the maintenance requirements and improve longevity of the buildings.

Cost Advantages

Aluminum coil weighs a lot less in comparison to the weight of other metals, which minimizes the lead of labor costs of transportation and installation. It has less cost of production, given that it forms fast and takes little time in fabrication.

Environmental and regulatory Advantages

The aluminum coil meets green building standards of LEED or BREAM because they provide recyclable low VOC coated products. It makes sustainable architecture.

Guidelines on how to Choose a Correct Coil

When selecting aluminum coil you should evaluate the following factors:

- Select suitable thickness and temper structural / deck drawing applications

- Take outdoor applications that are weather and corrosion resistant coatings

- Check pigment quality, guarantee of coating

- Use the matching coil width to fabrication equipment to maximize usage of materials, waste reduction.

Conclusion

The aluminum coil at aluminum metal.com is a union of strengths, durability, formability and sustainability. It uses a continuous roll which facilitates effective manufacturing. It has a long term performance because of the resistance against corrosion. It meets architectural requirements (mechanical, and industrial) by providing a variety of options (alloy, finish and coating).

Follow this guide to learn how aluminum coil can bring effective solutions to the roofing facades HVAC vehicles machinery and the signage. To custom order specifications and pricing visit the official page on aluminum coil products.