Introduction:

Aluminum is one of the most versatile metals in industrial and consumer use. Two common forms in which aluminum is supplied are aluminum foil and aluminum coil. While both share the same base material, they have distinct characteristics, thicknesses, and manufacturing processes that determine their suitability for different applications. Understanding these differences is essential for making informed material choices in industries ranging from packaging to construction.

1. Understanding Aluminum Foil

Aluminum foil is a thin sheet of aluminum rolled to a very small thickness, often less than 0.2 millimeters. It is produced through repeated cold rolling until the metal reaches the desired thinness. This process allows the foil to achieve high flexibility, excellent barrier properties, and a reflective surface.

Due to its ability to block light, oxygen, and moisture, aluminum foil is widely used in the packaging industry. Food packaging, pharmaceutical wraps, and household kitchen foil are common examples. The foil is also used in insulation applications for buildings and HVAC systems where it reflects heat effectively. In electronics, aluminum foil serves as a component in capacitors and cables.

The surface of aluminum foil can be plain, coated, or embossed depending on the application. Coatings can improve heat resistance, corrosion protection, or printability for branding purposes.

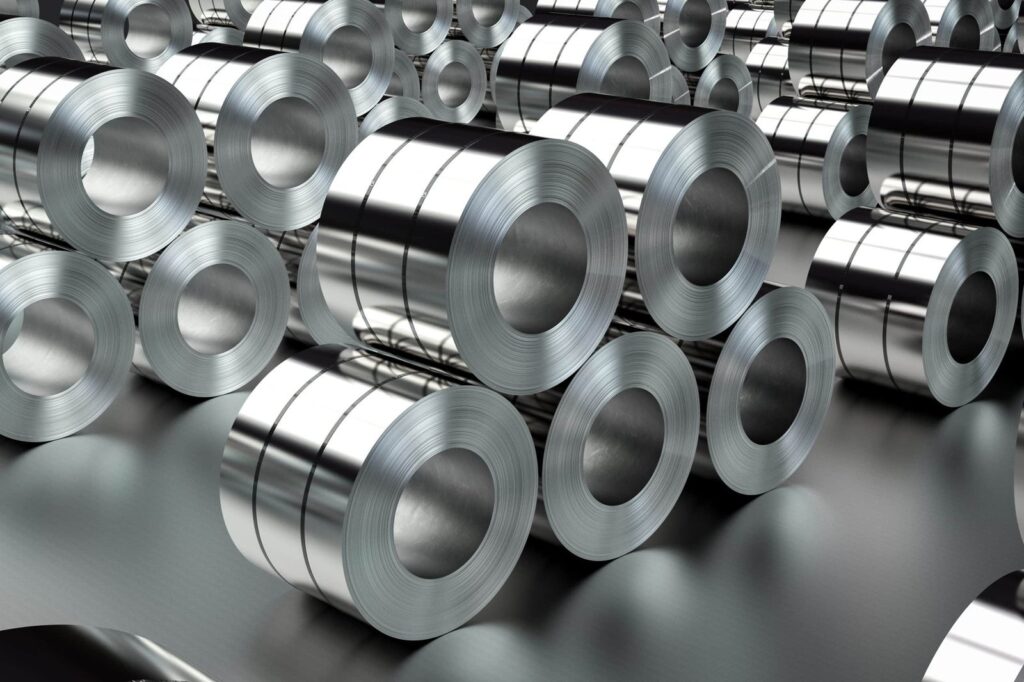

2. Understanding Aluminum Coil

Aluminum coil is a rolled aluminum product in continuous sheet form wound into large coils. Unlike foil, aluminum coil is much thicker, typically ranging from 0.2 millimeters to several millimeters in thickness. The production process begins with casting large aluminum slabs, which are then hot rolled and cold rolled to achieve the desired thickness before being coiled.

Aluminum coil is often further processed into aluminum sheets, panels, or other fabricated products. It is widely used in construction for roofing, cladding, and curtain walls. The automotive industry uses aluminum coil for body panels, while the transportation sector uses it for trailer bodies and shipbuilding. In manufacturing, it is used for producing appliances, signage, and industrial equipment.

Coils can be coated with protective paints or anodized to enhance corrosion resistance and appearance. This makes them suitable for outdoor and high-performance environments.

3. Differences in Thickness and Flexibility

The most obvious difference between aluminum foil and aluminum coil is thickness. Aluminum foil is extremely thin, flexible, and can be crumpled by hand, while aluminum coil is thicker and retains structural rigidity. This difference in thickness influences their strength, weight, and ability to be shaped or formed into products.

4. Differences in Manufacturing Process

While both begin as aluminum slabs, foil undergoes more rolling passes to achieve its ultra-thin profile. In some cases, two sheets of aluminum are rolled together and then separated to prevent tearing during the final stages. Coils, on the other hand, are rolled to the desired thickness and coiled without the need for extreme thinning.

5. Differences in Applications

Aluminum foil is used mainly for applications where flexibility and barrier protection are essential, such as in food wrapping, insulation, and electronics. Aluminum coil serves as a base material for structural and industrial applications, including building facades, vehicle bodies, and machinery components.

6. Surface Finish and Coatings

Foil typically has a bright reflective surface on one side and a matte finish on the other due to rolling methods. Coil surfaces can be mill finish, painted, or anodized, offering more variety in appearance for architectural purposes.

7. Cost Considerations

The cost of aluminum foil is influenced by its thinness and the precision rolling process, often making it more expensive per kilogram compared to coil. However, the coil requires more raw material due to its thickness, so total project cost will depend on the volume and specifications.

8. Environmental and Recycling Aspects

Both aluminum foil and aluminum coil are fully recyclable without loss of properties. Recycling aluminum saves significant energy compared to producing new material from bauxite ore. Industries are increasingly emphasizing recycled content in both foil and coil products to meet sustainability goals.

9. Choosing Between Aluminum Foil and Aluminum Coil

The choice between aluminum foil and aluminum coil depends on the end use. If a lightweight, highly flexible, and moisture-resistant barrier is needed, foil is the better option. For structural strength, durability, and further fabrication into panels or sheets, coil is more suitable.

Why Choose Aluminum-Metal.com

1. Vast Expertise in Aluminum Products

Aluminum-metal.com specializes in a wide range of aluminum products—from foil and coil to sheet and custom profiles. As a focused supplier, they can offer deep product knowledge and tailored advice, ensuring you find precisely what your project requires.

2. Outstanding Material Properties

Aluminum stands out across industries due to its unmatched combination of strength, lightweight, corrosion resistance, and excellent thermal and electrical conductivity. These features make it ideal for applications ranging from construction and packaging to electronics and automotive systems

3. Lightweight and Easy to Handle

In comparison to steel, aluminum is significantly lighter—about one-third the weight—making handling, transport, and installation more efficient and cost-effective

4. Naturally Corrosion Resistant

Aluminum forms a protective oxide layer when exposed to air, shielding it from rust and corrosion. This self-healing quality gives aluminum a resilience that outperforms many steel alternatives, especially in challenging environments

5. Highly Sustainable and Recyclable

Aluminum is fully recyclable without losing strength or quality, making it environmentally friendly and aligned with sustainability goals. Its recyclability also helps reduce production costs over time

Conclusion

While aluminum foil and aluminum coil share the same base metal, their differences in thickness, strength, and applications make each product uniquely valuable. Foil excels in packaging, insulation, and lightweight applications, while coil dominates in construction, transportation, and manufacturing.

Understanding their properties allows industries to choose the most efficient and cost-effective aluminum form for their specific needs.