Introduction

In the world of metals, aluminum stands out for its combination of light weight, durability, corrosion resistance, and recyclability. Among the many forms in which aluminum is produced, aluminum sheet and aluminum coil are two of the most widely used. Both forms originate from the same base material, yet their differences in presentation and handling give them unique advantages across various industries.

This comprehensive guide will explore the manufacturing process, characteristics, applications, and industry importance of aluminum sheet and aluminum coil, offering insight into why each form is vital in its own way.

Understanding Aluminum Sheet

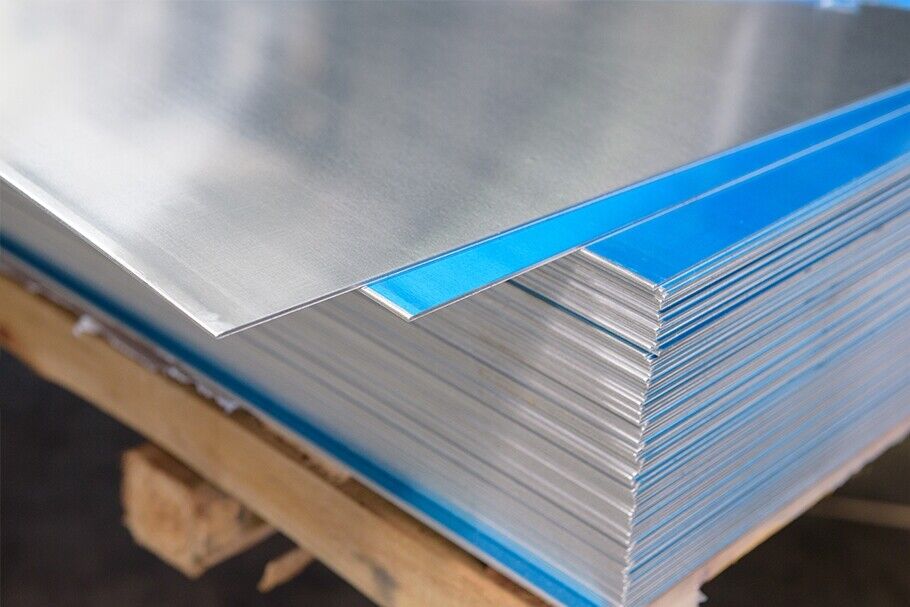

Aluminum sheet refers to aluminum that has been rolled into flat, thin pieces and cut into specific sizes. The thickness of sheets typically ranges from 0.2 mm to several millimeters. Aluminum sheets can be plain, embossed, anodized, painted, or textured depending on the intended use.

Key Characteristics

- Lightweight with High Strength – Aluminum sheets are easy to handle yet provide structural integrity.

- Corrosion Resistance – Natural oxide layers protect the surface from rust and deterioration.

- Aesthetic Flexibility – Can be polished, brushed, or color-coated for architectural applications.

- Thermal Conductivity – Effective in heat distribution, making it suitable for heat exchangers and cookware.

- Workability – Can be easily cut, bent, drilled, and welded.

Common Applications

- Construction and Architecture

Aluminum sheets are widely used for roofing, cladding, facades, and curtain walls. Their ability to resist weathering and retain appearance over decades makes them a preferred choice for modern building exteriors. - Transportation Industry

The automotive and aerospace sectors use aluminum sheets for body panels, fuselage skins, and structural reinforcements. The weight reduction compared to steel helps improve fuel efficiency and performance. - Appliances and Consumer Goods

Refrigerators, ovens, washing machines, and even laptops often feature aluminum sheet casings for durability and sleek appearance. - Marine Applications

In shipbuilding, aluminum sheet is used for hull plating and deck panels due to its resistance to saltwater corrosion. - Cookware and Kitchen Equipment

Aluminum sheets form the base of pans, trays, and bakeware, offering fast and even heat distribution.

Understanding Aluminum Coil

Aluminum coil is essentially a continuous sheet of aluminum wound into large rolls. This form is ideal for mass production because it allows manufacturers to process long lengths of aluminum without interruptions for cutting individual sheets.

Key Characteristics

- Continuous Length – Ideal for high-volume production lines.

- Storage Efficiency – Coils are compact for transport and warehouse storage.

- Versatile Processing – Can be slit, cut, stamped, or coated during manufacturing.

- Surface Finishes – Available in mill finish, painted, anodized, or laminated forms.

Common Applications

- Industrial Manufacturing

Coils feed machines that produce roofing sheets, siding panels, gutters, beverage cans, and automotive parts. - HVAC Systems

Aluminum coil is widely used in heat exchangers, air conditioning fins, and evaporator units because of its thermal efficiency and resistance to corrosion. - Packaging Industry

Rolled aluminum coil can be further processed into foil for food, pharmaceuticals, and beverage packaging. - Electrical Components

Coils are formed into busbars, conductor strips, and other components requiring electrical conductivity. - Signage and Decorative Panels

Pre-painted aluminum coils are cut and shaped for billboards, advertising panels, and building signage.

How Aluminum Sheet and Coil Are Produced

Both forms begin with the same base process: aluminum ingots are cast from molten metal, then rolled into thinner sections through hot rolling. After reaching the desired thickness, the aluminum is either:

- Cut into sheets – flat panels stacked for distribution.

- Rolled into coils – continuous lengths wound for industrial processing.

Additional treatments such as annealing, coating, or embossing can be applied to meet specific application requirements.

Choosing Between Aluminum Sheet and Coil

When to Use Aluminum Sheet

- When precise dimensions are needed.

- When individual panels must be handled separately.

- For decorative architectural features requiring polished or textured surfaces.

When to Use Aluminum Coil

- For automated production requiring continuous feed.

- When material needs to be transported efficiently in bulk.

- For large-scale cutting and stamping operations.

Advantages Common to Both

Regardless of form, aluminum sheet and coil share several universal advantages:

- Lightweight – Reduces transport and structural loads.

- Corrosion Resistance – Ideal for outdoor and marine environments.

- Recyclability – Fully recyclable without loss of properties.

- Versatility – Compatible with various alloys and coatings.

- Thermal and Electrical Conductivity – Suitable for energy-related applications.

The Importance in Modern Industry

Without aluminum sheet and coil, many sectors would face significant limitations in design flexibility, cost efficiency, and sustainability. In construction, these materials provide long-lasting façades and roofing solutions. In manufacturing, they enable large-scale, precision-made products. In transportation, they help meet energy efficiency goals by reducing weight.

Aluminum also plays a role in green initiatives. Its recyclability reduces environmental impact, while its lightweight nature contributes to fuel savings in vehicles and aircraft.

Summary Table of Uses

| Property / Feature | Aluminum Sheet | Aluminum Coil |

| Form | Flat, cut panels | Continuous rolled aluminum in coils |

| Best For | Precision panels, decorative applications | High-volume, continuous manufacturing |

| Typical Industries | Construction, aerospace, marine, appliances | HVAC, packaging, automotive, industrial fabrication |

| Storage & Handling | Stacked sheets, easier for small jobs | Compact rolls, efficient for bulk transport |

Final Thoughts

Aluminum sheet and aluminum coil each have unique strengths that make them essential to different stages of manufacturing and construction. Sheets excel in applications where size precision and surface aesthetics are paramount, while coils shine in environments demanding efficiency, scalability, and continuous production.

By understanding the properties, applications, and processing methods of each form, businesses can make informed decisions that maximize performance, cost savings, and sustainability. As industries continue to innovate, both aluminum sheet and coil will remain at the heart of modern material solutions.