Introduction

Aluminum foil has transcended its humble beginnings in the kitchen to become a key material in countless industries. Manufactured in various grades and thicknesses, the aluminum foil series plays a vital role in packaging, insulation, energy conservation, and medical applications. The versatile material shows advantages in thermal conductivity together with weight reduction and barrier properties which made it vital in both industrial and consumer landscapes.

This comprehensive guide explores everything you need to know about the aluminum foil series, including its types, benefits, applications, technical specifications, and why it’s a cornerstone material in global trade.

What is the Aluminum Foil Series?

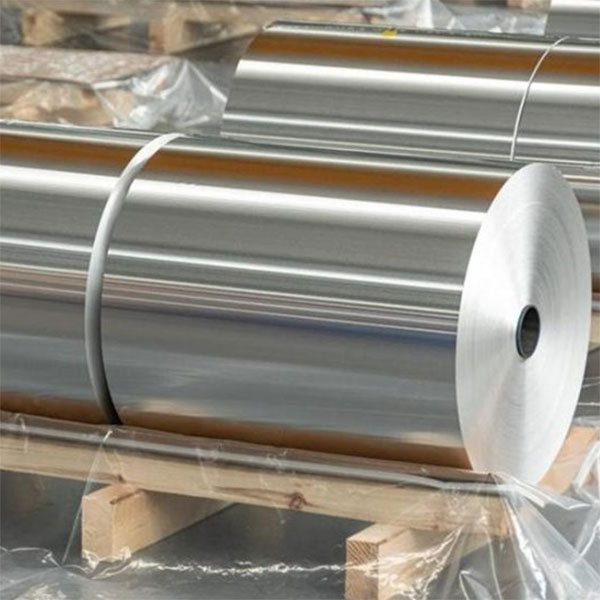

The aluminum foil series refers to a group of aluminum foil products classified based on their alloy composition, thickness, temper, and application use case. Fabrication starts with aluminum ingots before aluminum foils obtain their required qualities through treatments that bolster strength and malleability and improve corrosion resistance.

Among foil products the most popular chemical the aluminum industry uses stands as the following series:

- 1000 Series (Pure Aluminum Foil) – High purity and corrosion resistance

- 3000 Series (Manganese Alloy) – Enhanced strength and ductility

- 8000 Series (Composite Alloy) – Preferred for pharmaceutical and packaging applications

The foil products of each series achieve their best performance through specialized design methods that follow ASTM, ISO and EN international quality requirements.

Types of Aluminum Foil Products

The aluminum foil series includes several specialized types depending on end-use:

Household Aluminum Foil

This type of aluminum foil serves as a useful edible surface which people bring into their kitchens for grilling and kitchen storage needs. The material functions as a heat retainer while shielding food from contaminants and sustaining liquid amounts in cooked goods.

Industrial Aluminum Foil

Industrial aluminum foil belongs to this type category and finds application in construction projects and automotive components as well as cable protection functions. Due to its unique properties aluminum foils demonstrate high resistance to heat together with mechanical strength.

Pharmaceutical Foil

The 8000 series aluminum foils compose this type which displays non-toxic qualities along with high malleability and sterility. Modular aluminum sheets with sterile properties serve the packaging needs of blister packs at tablet level and capsules and sachets.

Laminated Foil

Plastic and paper coating is applied to this foil material to generate multi-layer packaging films. The foil finds applications within the packaging of snacks as well as safeguarding dairy products and protecting beverages.

Technical Specifications

Understanding the technical data of aluminum foil is crucial for manufacturers and procurement managers:

- Thickness Range: 0.014 mm to 0.2 mm

- Width Range: 20 mm to 1600 mm

- Temper: O (soft) H18, H24, etc.

- Alloy Grades: 1050, 1060, 3003, 8011, 8021

- The materials are available in three different surface types including matte bright on one side and brightness on both sides and embossed foil among others.

- Coatings: Epoxy, polyester, PE, or customized layers

The needed specifications diverge based on how the final product will serve such as thermal insulation and electromagnetic shielding and food preservation alongside medical safety requirements.

Top Benefits of Aluminum Foil

Excellent Barrier Properties

Aluminum foil is impermeable to light, air, and moisture. The material shows excellent performance as protective packaging since it works well for protecting food products along with pharmaceuticals and cosmetic goods.

Heat Reflectivity and Conductivity

This material provides exceptional radiant heat reflection at 97% and offers efficient heat and electricity conduction which makes it perfectly suitable for HVAC insulation applications and electronic components and automotive heat shield solutions.

Recyclability

Aluminum stands out as a recyclable material that maintains its original quality in every cycle thus accomplishing much lower environmental consequences than plastic packaging.

Lightweight and Malleable

The forming ability of foil remains intact while it retains its shape because this allows manufacturers to create unique packaging formats that reduce shipping expenses.

Chemical Stability

The material takes well to most food products and chemical substances therefore proving itself both dependable for medical use and suitable for food packaging.

Applications Across Industries

Food & Beverage Industry

Used in wrapping, sealing, and lining, aluminum foil keeps food fresh and extends shelf life. Following are packaging applications that need its special protection because they are used for ready-to-eat meals and dairy products and baked goods.

Pharmaceutical Industry

Foil consists of two key medical applications within blister packs and strip packaging to protect medicines from environmental factors through bacteria defense and regulatory compliance.

Building & Construction

Aluminum foil serves as a vapor barrier, heat insulator, and noise-reducing layer in walls, ceilings, and HVAC ducts. Installation professionals use foil-faced materials extensively for building both residential and commercial construction projects.

Electronics and Automotive

The foil works as both an EMI blocker and a heat shield in circuit boards as well as batteries and vehicle insulation systems.

Sustainability and Global Demand

The aluminum foil market is expected to grow steadily in the coming years, driven by global trends in eco-friendly packaging and urban infrastructure development. With regulatory bans on plastic packaging in many regions, aluminum foil emerges as a more sustainable alternative, aligning with green manufacturing goals. Leading producers in the industry make investments to establish recycling systems alongside implementing renewable energy adoption programs and waste reduction measures for advancing their environmental footprint in foil manufacturing.

Choosing the Right Aluminum Foil Supplier

When sourcing aluminum foil for industrial use, it’s important to consider:

- Companies should validate suppliers that meet the requirements of ISO as well as ASTM and REACH certifications.

- Selection of vendors should include businesses that make aluminum foil products with personalized thicknesses as well as customized coatings and individualized cut formats.

- Global Reach: Choose partners with reliable international logistics.

- A reputable supplier will help clients select suitable materials by providing expert advice according to their product requirements.

The Aluminum Metal company delivers customized foil products to clients through their extensive metallurgical experience.

Conclusion

The aluminum foil series is much more than a shiny kitchen helper. Panalyst offers high performance material applications which support advancements in food safety and construction along with technology and healthcare needs. Whether you’re an engineer, product designer, or sustainability advocate, understanding the types, strengths, and uses of aluminum foil can help you make smarter decisions for your business and the planet. With its unmatched versatility, durability, and environmental promise, aluminum foil continues to shape the future—one thin sheet at a time.