Introduction

Aluminum sheet: aluminum sheet is one of the most widely used material in the contemporary manufacturing business. Available as stock with aluminum metal.com in different thicknesses and finishes to the surface it meets the demands of many industries. Its outstanding characteristics are lightweight construction, resistance to corrosion, good formability, good strength to rely upon and environmentally friendly recyclability. This paper examines the various advantages of Aluminum sheet and highlights the typical applications in various industries like the construction, automotive, aerospace, electronics and interior design industries.

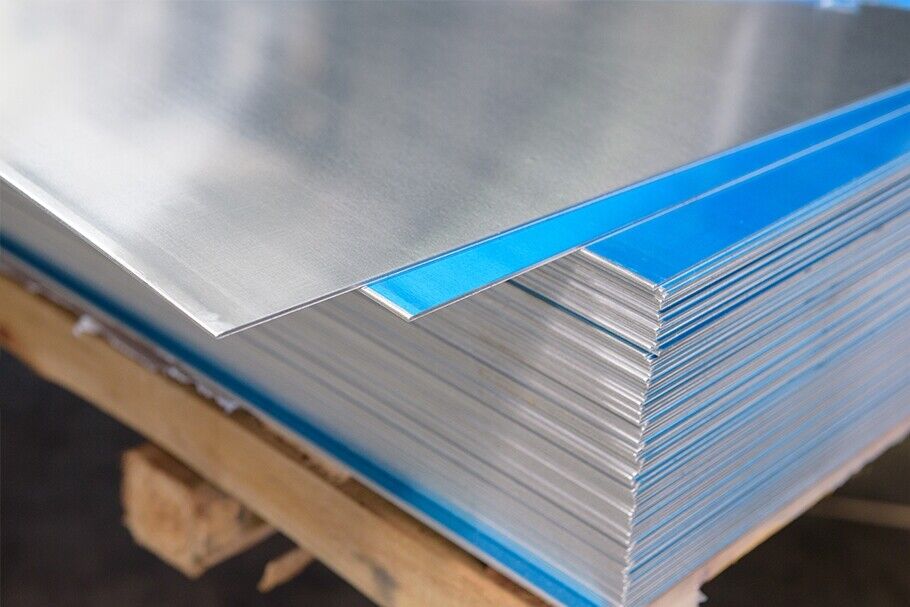

Getting to know about the Aluminum Sheet

An aluminum sheet is rolled metal form in flat form in a mill finish or modified form. Having a thickness range varying between thin foils and thick plates, it can be utilized both in the panel and engineering applications. Aluminum sheet aluminum.metal.com is durable and has a strong base which could extradite this metal forming, fabrication coating or direct usage in whatever the finish or dimension.

These are the Main Advantages of Aluminum Sheet

Light Weight Strength Combination

Aluminum sheets have a great strength to weight ratio. They provide structural support without a weight burden such as steel or iron. This has made them suitable to use in places where weight reduction is important- such as car body panels to architecture facades.

Corrosion Resistance

Aluminum is reported to naturally have an oxide layer on the surface that provides high weather protection, moisture and most chemicals resistance. This resistance subjects it to application in outdoor structure, roofing panels, auto bodies, and boats.

Formability and machinability

Aluminum sheet is easy to cut, bend, stamp, weld and form due to great ductility. This renders it an ideal material in architectural paneling, machine enclosure, signage’s boards, decorative molding or HVAC parts. It also has a smooth finish which allows silk stuff printing or paint.

conductivity The electrical conductivity may also act as a transducer of thermal conductivity to electrical conductivity. This aspect is most often unfortunate and destabilizing.

Aluminum is a good conductor, or it conducts heat and electricity. Its sheet form finds a large application in heat exchanger panels, electrical housings, chassis, enclosures and thermal transfer products.

Recyclability and Sustainability

The ability to recycle aluminum is extremely high and without compromising its quality making it one of the key eco credentials of aluminum. Aluminum recycling takes only a small bit of the energy the metal takes in its primary production. The utilization of recycled aluminum sheet lessens carbon impact and complies with environment friendly building and manufacturing tactics.

Cost Efficiency

Aluminum sheet reduces costs of production and logistics because of low weight, and ease of processing. It has good corrosion resistance, thus reduces maintenance cost. And recycling provides value because it recovers material using little energy.

Aesthetic Versatility

To fulfill aesthetical needs aluminum sheet can be anodized, painted, embossed, or brushed. It is usual in decorative cladding, current building facades and interior ceiling remains, as well as art designs. It can hold finishing and it is perfect with facades and interiors that are long lasting.

General Applications in Industries

Building and Design

Architectures and constructors use the aluminum sheet in exterior wall panel, roofing components, door and window frames, vent hood, fascia panel, soffits assembly. The fact that it can be formed into profiles and can be given finishes has made it suitable towards curtain wall cladding and other modern architecture statements.

Automotive Manufacturing

The panel such as hoods, doors, trunk lids, body panels, interior trim and anybody chassis are made up of the aluminum sheet. It is a material that is light and enhances fuel consumption and low emissions and has sufficient rigidity to support safety-related and stylish elements.

Aerospace and Aviation

Aluminum sheet fuselage panels, wing and control surface materials are widely used in aircraft design as they are lightweight and strong, do not fatigue, and can endure repeated pressurization and pressurization decompression.

Electronics and Electrical Engineering

Aluminum sheet is used in panels, chassis, housings, heat sinks, shielding covers and enclosures because of their heat spreading ability, EMI shielding and the length of use due to lack of corrosion.

Marine and Transportation

Aluminum sheet is common in making boats, the paneling of ships, the inner compartment of ships, rail car siding, the skin of trailers, and the panel of trailers.

Design and Consumer Goods

The bodies of house appliances, furniture panels, sign devices, light fittings, cookware covers, decorative screens, and store displays enjoy the finishing possibilities of the sheet, along with its strength and the flexibility of aesthetics.

Industrial Fabrication

This material laminates best in ductwork, tank panels, machine housings, safety guard, part trays, mounting plates and structural brackets where clean edges and wieldable seams are a benefit.

Wear and Durability Durability RTP Weather Performance

Aluminum sheet is capable of resisting changes in temperature, ultraviolet rays, rain and wind. These attributes give it the best fit when it comes to outdoor applications where there is a potential of rusting or corrosion of other metals. It is also resistant to salt based corrosion common in coastal areas and hence it is best suited in the construction of marina buildings and ground level installations.

Surfaces Treatments and Finishes

In order to comply with protective requirements or aesthetic requirements the sheet may be augmented by:

Anodizing

Formation of a thick oxide coating that is impervious to scratching, fading and wear due to the environment. It is possible to dye it to different colors retaining the metallic appearance.

Coating and Coil Coating

Pre painted aluminum sheet is suitable to provide a complete surface protection as well as decorative design on the façade and ceiling of buildings inside.

Installation and Fabrication Simplicity

Aluminum sheet can be easily worked on using either the hand or the CNC machine. It facilitates quick forming that overlooks rejection of tool wear. Facade installation Normally rivets or panel clips may be used during installation. It may be bonded or spot welded in enclosures. Such benefits decrease the amount of labor, shorten the time of project delivery, and guarantee clean results.

Green Building and sustainability

Certification programs such as LEED usually provide credits on high recycled content materials as well as end-of-life recyclability. Cladding or roofing using aluminum sheet help in realization of sustainable building objective. Lifecycle performance assists in achieving energy and carbon goals.

Conclusion

Aluminum sheet is an outstanding product which provides a perfect combination of strength, low weight, resistant to corrosion, easy to machine and has beauty in terms of versatility. Through building facades appliance bodies vehicle panels or structural enclosures, it’s worth keeps increasing in any industry.

Aluminum sheet Aluminum metal.com has the perfect choice of aluminum sheet owing to its eco-friendly recyclability as well as performance. This makes the product user friendly to architects-manufacturers fabricators and designers seeking products of good durability and quality in modern needs.

To get the price of specification or custom forms go to the official page of the product aluminum metal.com product aluminum sheet