Introduction

Aluminum is a flexible and very common metal. This material finds a variety of processed forms appropriate in various commercial, industrial, and architectural works i.e. at aluminum-metal.com, you can find it in a variety of processed forms. Aluminum foil and aluminum coil are considered to be two major types of products. The two products although being made of aluminum have very different uses because they are of different thickness, flexibility, strength and end-use design.

In this article, the fundamental distinctions between these two products will be examined on the basis of the information that is present on the product pages of these products. Depending on whether you are a procurement manager, manufacturer, contractor or consumer this guide will give you a clear conscience as to which material is right to your application.

What is Aluminum Foil?

Aluminum foil is a piece of aluminum wrapped in roll form. On the product page of aluminum-metal.com, it comes out that the foil can be ordered with varying thicknesses and widths implying that it can be custom made to suit a particular need. The foil is made of high density aluminium and undergoes rolling processes that make them consistent, smooth and pliable.

Key Characteristics

Thin and Lightweight: This foil has been manufactured as having minimum thickness thus fitting in those chores that involve wrapping or lining and insulating.

• Roll Form: This product was supplied in roll form and this makes them easy to handle, transport and apply in different settings.

• Flexibility: It is thin hence can form/bend around things without shattering or losing its flexibility.

• Surface Finish: In general, aluminum foil is bright and clean in finish that it efficiently reflects both heat and light.

• Adjustable Sizes: It can be customized to different applications because of its availability in multiple width and thickness.

Typical Applications

Based on the available information, the type of aluminum foil provided is suitable in such industries that needed micrometer accurate thin barrier films. Areas of general application can go as follows:

- Pertaining to food, pharmaceuticals, or chemical packaging

- Thermal protection and thermal insulation

- Reflectivity used in decoration works

- Cable load Bending or wrapping or shielding

- Cooking and baking (home and business)

What Is an Aluminum Coil?

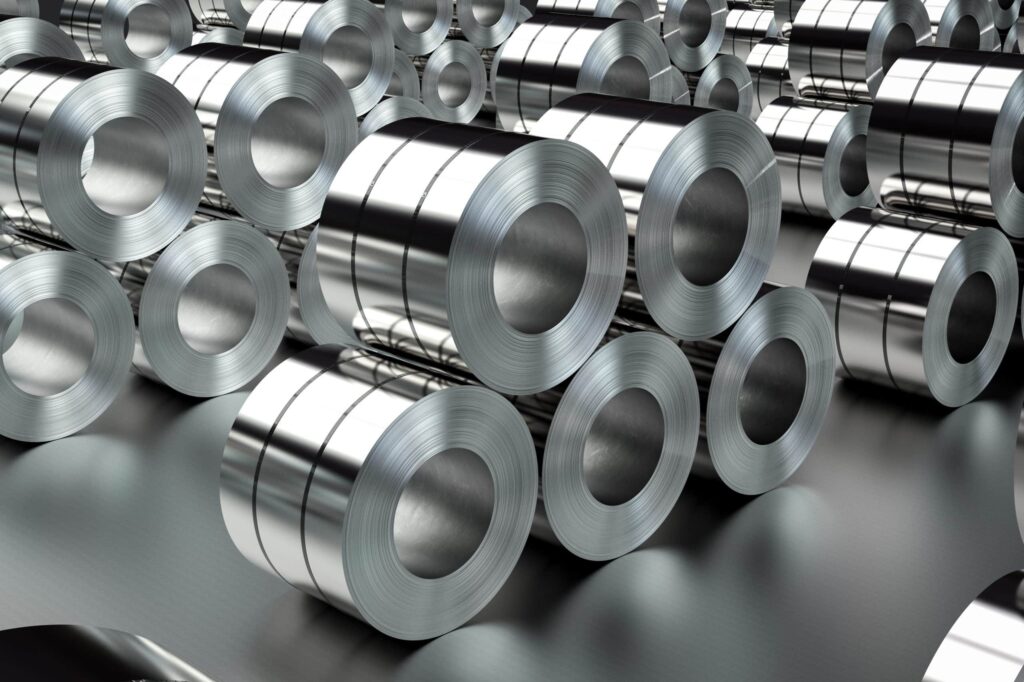

Aluminum coil is another product which is different in terms of physical structure as well as its purpose. As stated on the aluminum-metal.com page of products, aluminum coils are broad continuous bands of aluminum that are rolled into big rolls. They are commonly applied in more demanding manufacturing or building industry.

In contrast with foil as material used predominantly to wrap and pack, such a base material as aluminum coil is used as part of the roofing system components, wall cladding and curtain walls, decorative and structural elements.

Key Characteristics

• Compositions: Aluminum coils are quite thick compared to the foil hence they can be used as structural applications or as load-bearing entities.

• Continuous Length: The coils are cut and unbroken long coils which are perfect in feeding the machine, that needs continuous flow of metal.

• Strength: Aluminum coils have acceptable strength that can be used in form, punch and fabrications after proper tempering of the coils.

• Industrial-Grade Surface: These coils can be coated, anodized, or painted according to the end use requirement which makes the coils more durable and pleasing to look at.

Common Uses

Judging by the description of the product, the Aluminum coil is mostly applicable in the construction and manufacturing industry. It is usually used in the following ways:

- Exterior walls construction

- Roofing and roof accessories

- Curtain wall panels

- Frames of the window frames and doors made of aluminum

- HVAC or heat exchanger stock fin or fin stock

- Electrical and mechanical parts

A Guide to Selecting the Correct Material

The decision between using aluminum foil or aluminum coil is solely reliant on that which you intend to use it as well as its intended purpose. The products descriptions in the site of aluminum-metal.com come as important guides on the appropriate choice.

The Case of Selecting Aluminum Foil

In case you need thin and plastic top aluminum sheets.

• To package, or insulate, or reflectively wrap.

• In those instances of working with the environments that are low-temperature or indoor.

• Tasks that use a light material that needs to be temporary.

• It is perfect in case of temporary protection, heat shielding, or hygienic wrapping.

The Aluminum Coil Sheet and how it should be used.

- When your product requires strength, structural integrity or durability.

- To be used in roofings, wall cladding or window framing.

- When you require great volumes to support continuous production.

- In weather-exposed environments or long-life environments.

- Ideal in machining and formation of industrial products.

Having at the back of your mind what exactly your project entails, as well as what each of the different forms of the material has to offer.

Customization Options

Aluminum foil as well as aluminum coil offered by aluminum-metal.com comes in various grades and sizes. Though the foil is mostly delivered on rolls so it can be easily used flexibly, the coil possibly provides a possibility to see alternative alloy series, surface treatment and finishing. They may be plain mill finish, coat with color or anodized finishes to provide beauty as well as protection.

Industrial Significance of Aluminum Product

The aluminum foil and the aluminum coil are significant in various industries. Although both of the products are meant to be applied at the ends of different products, the two things have the following advantages:

• Restistance to corrosion in tough spaces

• High thermal conductivity of temperature sensitive processes

• A lightweight structure to facilitate and make shipping and handling economical

• Full recyclability, environmental friendly production

To the architects, engineers, manufacturers and the suppliers, the study of such aluminum products according to the official specifications guarantees the efficiency of the material, quality control as well as the adherence to the standards of application.

Concise Report on Salient differences

In a nutshell, the principal differences between the two products boil down to the following since these are the official descriptions of the products in the aluminum-metal.com:

Aluminum Foil is made in a light-duty form whereby it has to be thin and flexible. One can easily deal, keep and use it in temporary or protection purposes. Special to food, pharmaceutical and insulation.

Aluminum Coil is customized; it is dedicated to structural and heavy-duty use. It provides robustness, flexibility in manufacturing, and adaptability in those conditions where durability and performance are a paramount concern. Especially suitable to the building, structure, and mechanical systems.

Final Thoughts

Aluminum-metal.com is supplier of good quality aluminum materials of different forms. It does not matter whether you require aluminum foil to package or insulate and aluminum coil to construct or architect, the product selection criterion should be based on the application you intend to use it and the physical requirements you want it to satisfy.

By choosing the appropriate aluminum product to use in your project, you enjoy the natively superior properties of the material and the quality that an old hand in the game like the supplier offers.